NEWS

"HYDRAULIC DIGITAL SOLUTIONS", THE WALVOIL ANSWER

The modern mobile machinery market demands a constant increase in productivity and performance, together with lower operating costs, greater efficiency and reduced emissions, in favour of sustainability and social responsibility.

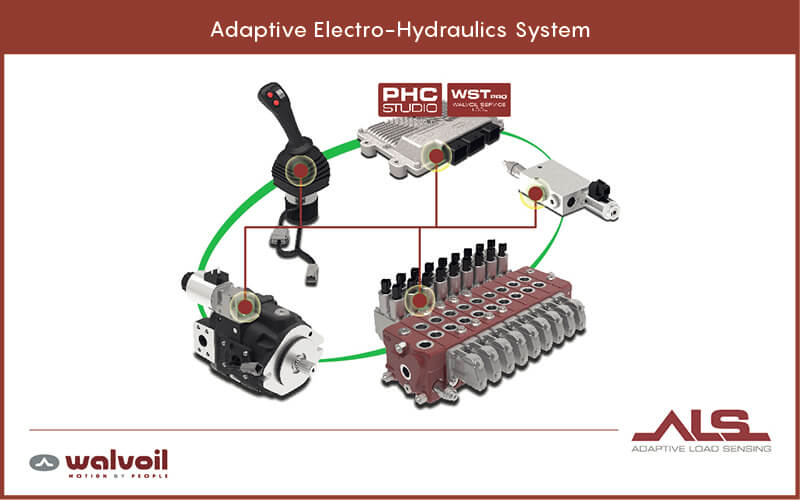

We respond through our new Hydraulic Digital Solutions, composed of modules (products, software, systems, applications) focused on energy efficiency towards the "ZERO emissions" trend, development of architectures for safety functions, automation in mobile hydraulics, connectivity and control of operating parameters, human-machine interface (HMI) and an electronic control unit with customizable modular software developed by Walvoil (PHC STUDIO).

NEWS

ALS ADAPTIVE LOAD SENSING SYSTEM - EVOLUTION

Part of the new Hydraulic Digital Solutions, the ALS received the Eima 2020-21 Technical Innovation Award, and has since continued to gain market acclaim.

The ALS, whose tests carried out in collaboration with telehandler manufacturer Dieci have confirmed a reduction in consumption of more than 5-6%, can be used as an integral part of the directional control valve or fitted on the variable displacement pump.

With the ALS, Walvoil presents a new generation of control systems based on electronic circuits and algorithms. Advanced software allows the best operating performance and reduced dissipation.

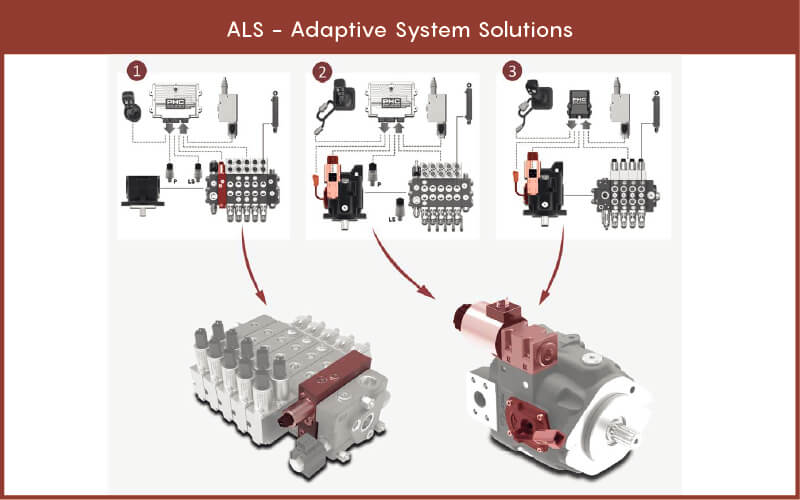

In order to offer extreme versatility and adapt to the machine's performance and system requirements, Walvoil offers the system in three different circuit solutions.

Find out more about the different applications as well.

Read all…

NEWS

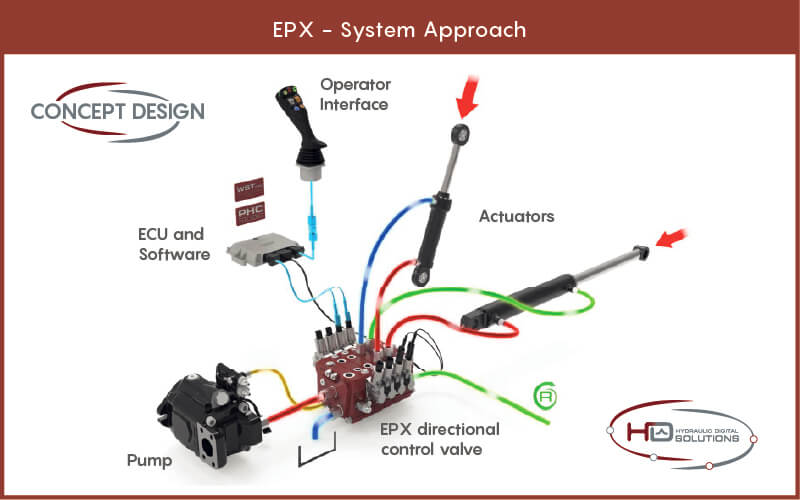

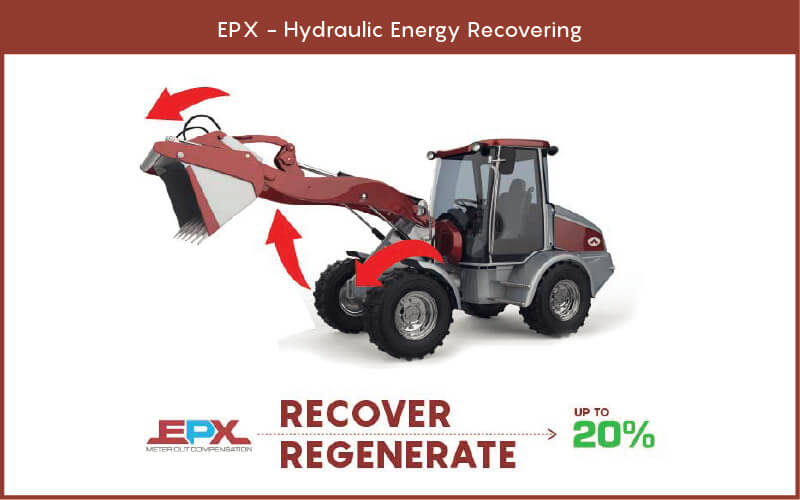

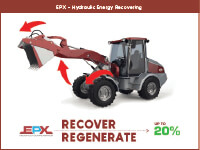

AT BAUMA 2025 THE EVOLUTION OF THE EPX - ENERGY RECOVERY VALVE CONCEPT

Hydraulic systems have evolved to maximize the predictability of actuation speed.

Flow compensation is a well-known technology that mechanically corrects the actuator speed if it exceeds the operator's demand due to inertial load. This is achieved by a mechanical device, which introduces a pressure drop to limit the flow when necessary.

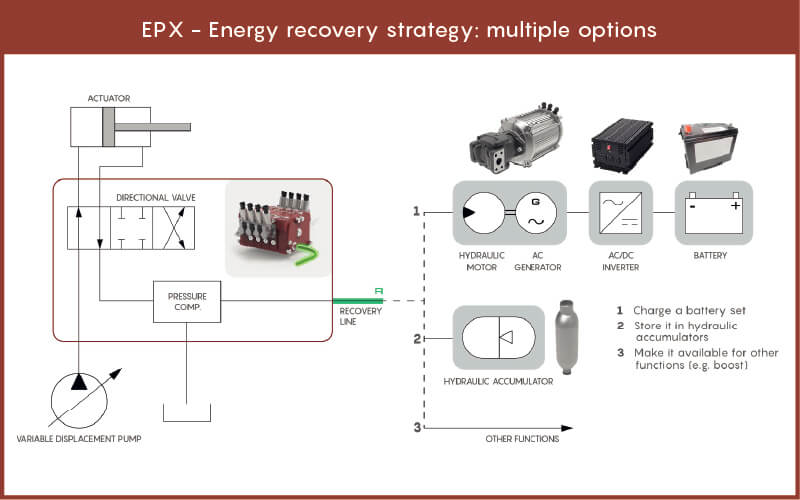

EPX, part of Walvoil's Hydraulic Digital Solutions, innovates beyond industry standards with a three-way device that not only limits the actuator speed, but also recovers stored gravitational and kinetic energy. Tests on wheel loaders have shown energy savings of 20% by combining recoverable energy and reduced compensation losses.

Read all…

NEWS

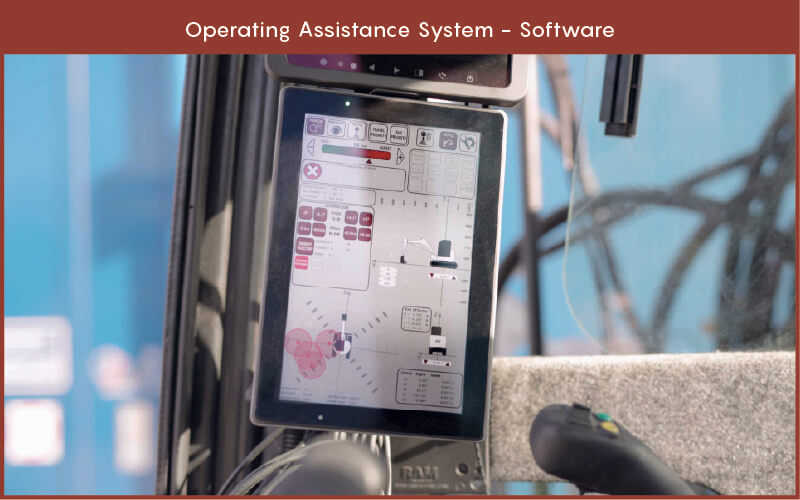

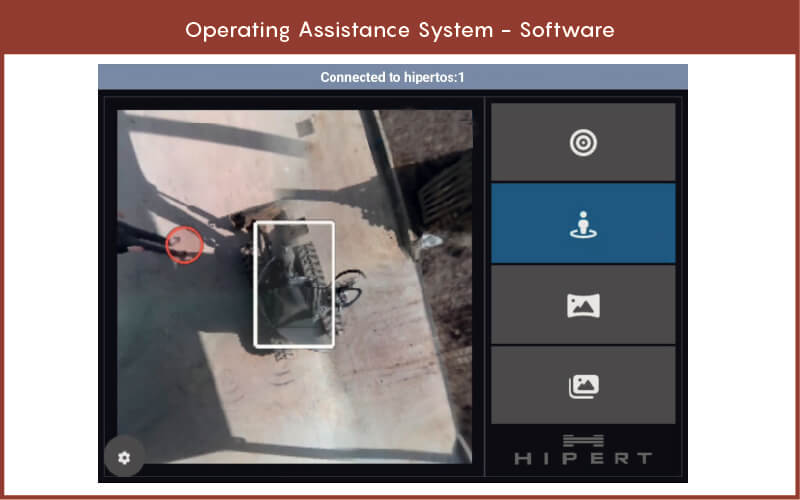

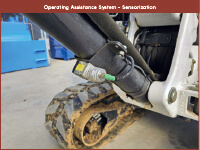

New Operating Assistance System for midi-excavators

There are many types of off-highway vehicles in the world and all of them need trained operators for their use, especially for more complex jobs that require constant attention and precision. The operator must also pay attention to his own safety and to that of the people around him; this can increase his level of stress. Walvoil's Operating Assistance System for midi-excavators incorporates concepts from the robotics sector into the control of the hydraulic arms of excavators in order to automate the manual control of each joint to obtain higher performance and increase operational safety.

Discover how.

Read all…

NEWS

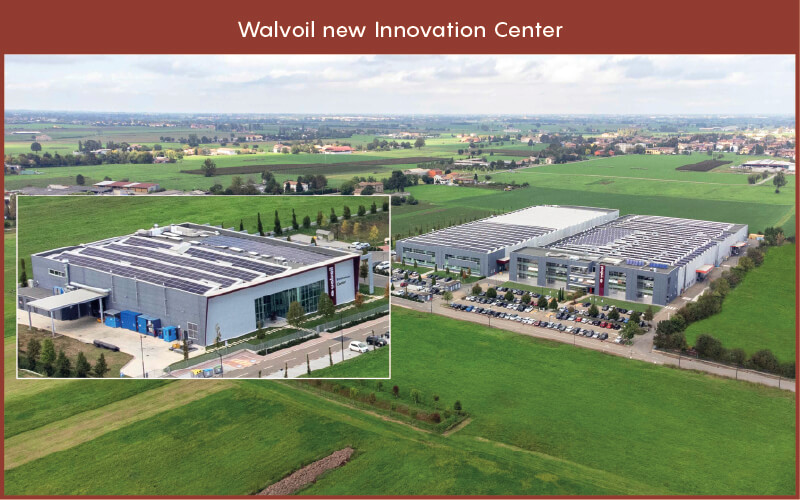

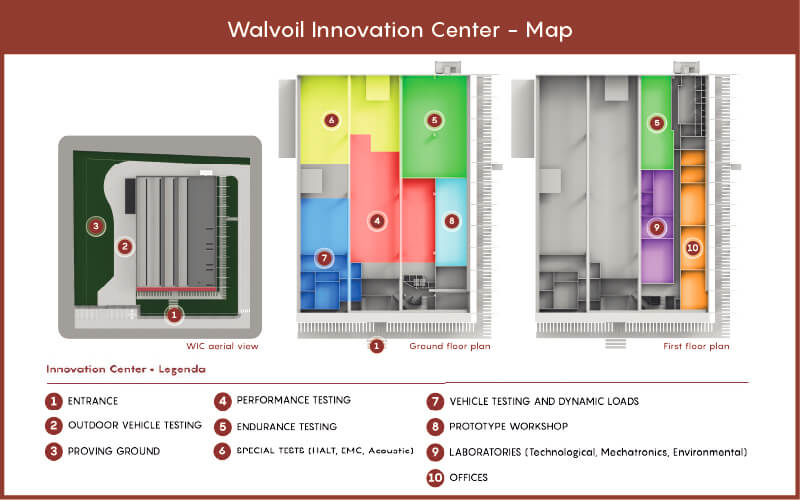

Walvoil's Innovation Center serving system integration and flexibility on off-highway vehicles

Walvoil's new Innovation Center is now fully operational. Born in 2023 as part of an investment plan of over thirty million euros, its main aim was to become a Research center of excellence in the field of hydraulics, and to enable the company to expand and deepen its innovation, development and testing capabilities.

An evolution of the previous Test Department, the center covers over 3000 m2 and an external area of almost 2000 m2 dedicated to vehicle testing, and can count on around 30 specialized personnel.

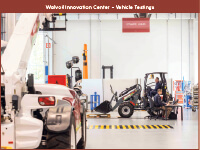

It is above all in the activities on vehicles available at the Innovation Center, either its own or those of customers, that Walvoil is committing many of its resources, so as to make a difference both in the development of more advanced and high-performance components, as the mobile machinery market now demands, and in the design and application of greater integration with electronics and the creation of greater added value in terms of system flexibility.

Read all…

NEWS

PWLS variable displacement piston pumps: range completed

Walvoil completes the new PWLS series pump range with variable displacement pistons. With the release of the PWLS3 pump, the available displacement now starts at 23 cm3/min. and goes up to 80 cm3/min. with a maximum working pressure of up to 280 bar (4050 psi).

The range features different displacement control solutions, with optional speed sensor:

- Pressure control

- Pressure control with LS signal

- Pressure control with LS signal and torque control.

The PWLS Series piston pumps also boast a high degree of construction robustness combined with the possibility of very compact tandem configurations.

Read all…

NEWS

SAE cavity valve range expanded

Walvoil expands its range of SAE cavity valves and introduces new electric proportional directional cartridges. Walvoil's proportional electric directional cartridges are designed to share the components of traditional valves, allowing for high industrialisation, broad versatility and the development of common options.

In parallel, the range of logic valves is also completed, up to the SAE16 cavity, increasingly used in the realisation of complex circuits with special functions.

Read all…