NEWS

THE NEW "HYDRAULIC DIGITAL SOLUTION" PRODUCT LINE

The modern mobile machinery market demands a constant increase in productivity and performance, together with lower operating costs, greater efficiency and reduced emissions in favor of sustainability and social responsibility.

Various research and studies in the field point out that up to 40% of the energy supplied to the hydraulic system of the operating machine is dissipated by the limited efficiency of the components and the pressure drops due to the metering and control of the movements.

The problem is even more evident on electrified applications, where energy efficiency is synonymous with prolonged range and reduced battery capacity.

Walvoil illustrates how to increase efficiency of the hydraulic system and its components with the new Hydraulic Digital Solution product line (ALS - Adaptive Load Sensing Systems and EPX technology), which guarantees a consumption reduction up to 25%.

NEWS

ALS - ADAPTIVE ELECTRO-HYDRAULIC

SYSTEMS FOR THE EFFICIENCY OF MOBILE MACHINES

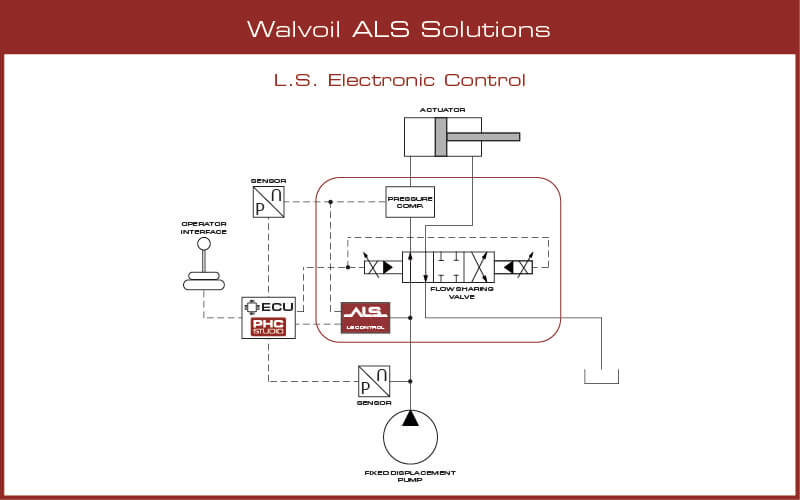

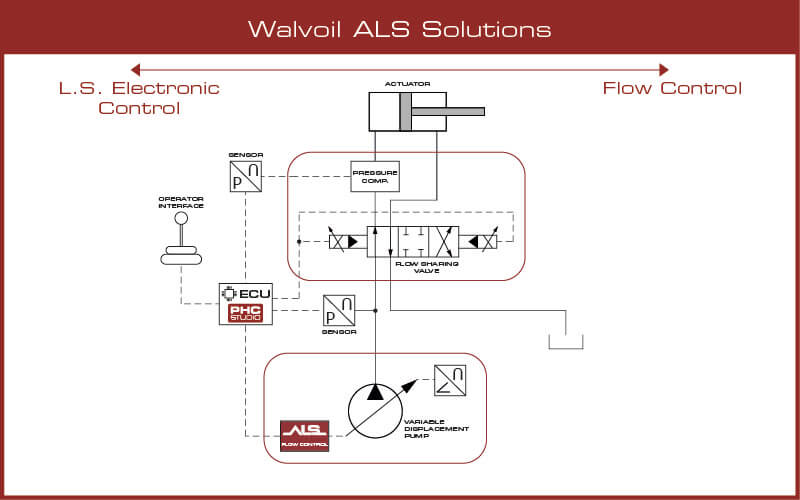

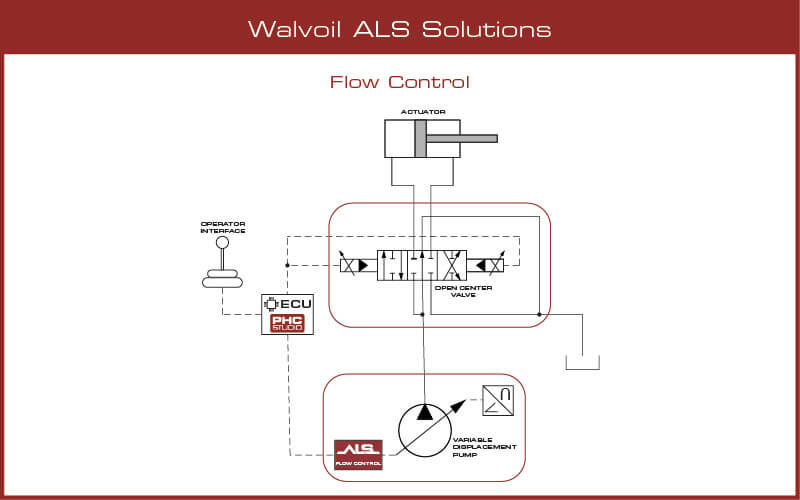

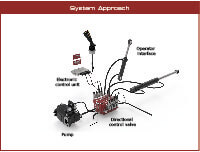

ALS is a synergistic set of components for the efficiency of mobile machines. The joint control of the hydraulic directional control valve and the pump makes it possible to cut down pressure drops due to the pressure margins of the metering system. At the same time, a series of logics are available to improve machine control, productivity, and driving comfort.

Walvoil offers three different ALS solutions to provide extreme versatility and adapt to the performance and system requirements of the machine.In fact, the ALS system can be used as an integral part of the hydraulic directional control valve or fitted to the variable displacement pump. The studies conducted and the application of ALS to various types of vehicles demonstrate energy savings of up to 5%.

Read all…

NEWS

EPX - HYDRAULIC ENERGY RECOVERY

SYSTEM FOR RECOVERING HYDRAULIC ENERGY THROUGH METER-OUT COMPENSATION TECHNOLOGY

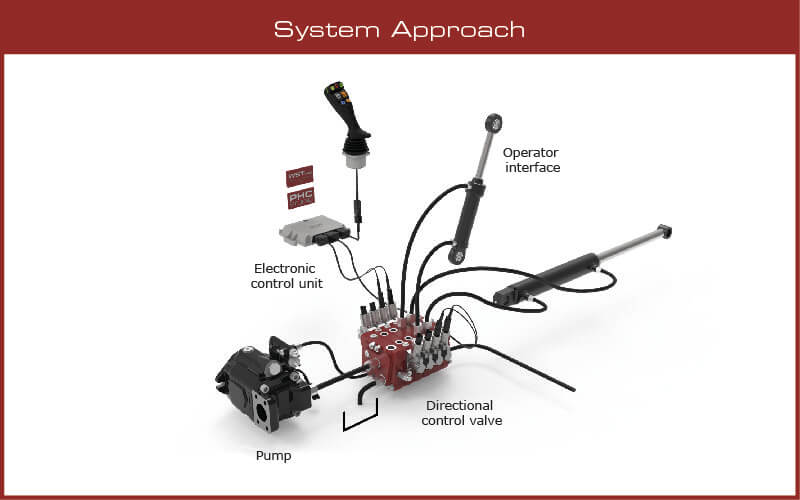

EPX technology is made of a Flow Sharing directional control valve, an electronic joystick, a Load Sensing pump and an electronic control unit with customizable modular software developed by Walvoil (PHC STUDIO).

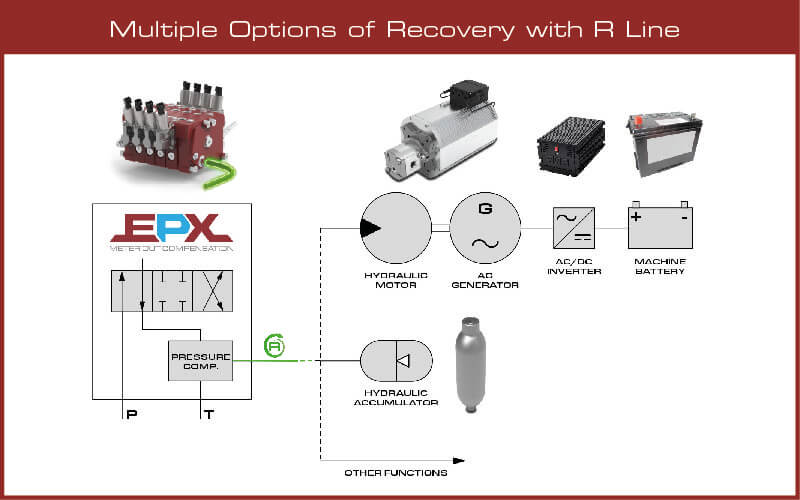

EPX technology is based on new compensator's function with a recovery line R powered by flow in pressure (Power).

Once the recovered flow is available in the line R, its management depends on the choices of the equipment manufacturer. It is possible to regenerate the recovered flow into the system directly, to store it in a hydraulic accumulator, or to transform it in electrical energy and store it in a battery.

The EPX system is capable of lowering consumption and returning a share of energy, with overall energy savings of up to 20%, depending on the type of application.

Read all…

NEWS

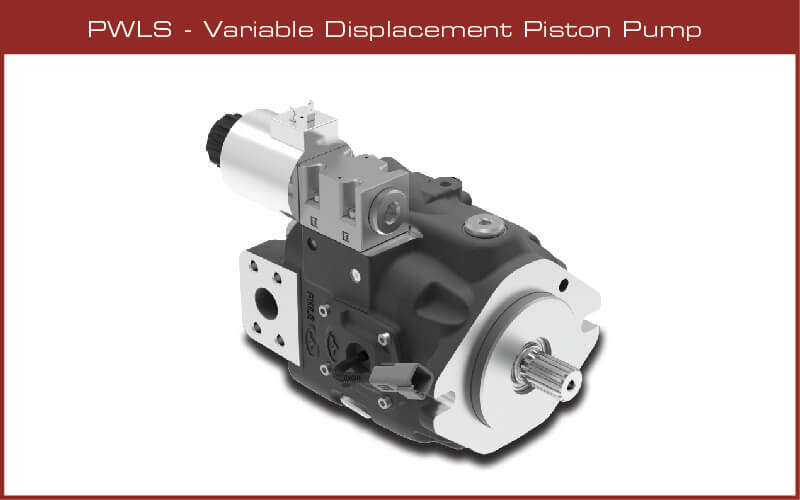

PWLS - AT EIMA THE NEW VARIABLE DISPLACEMENT PISTON PUMP

The new PWSL - variable displacement piston pumps will be introduced to the agricultural sector at eima. PWLS series offers all the useful features for a new generation of mobile hydraulic implement pump. Its compact design allows installation in narrow spaces and its reactivity and stability grant the maximum comfort for the operator. The design and production cycle allow heavy duty operation in the medium pressure range, with a nominal service pressure up to 280 bar (4050 psi).

Additional features like sensor cavities, compact tandems and various control manifolds complete the offer of this new generation of Walvoil piston pumps. The typical application varies from construction machines like skid steer loaders, telehandlers and excavators, to lifting and transport ones like aerial lifts and fork lifts.

NEWS

NEW TRACTOR SOLUTIONS

The new Walvoil Tractor Solutions allow you to meet all the requirements of the most sophisticated and modern technologies on the latest generation tractors.

The Walvoil solution introduced at eima includes the new DKP120 sectional valve, the CAN bus NG5 electronic module and the Hitch control valve.

The DPK120 is a pre-compensated sectional valve for open/closed centre circuits, specifically designed for tractors and front loaders. It is equipped with a wide and flexible range of options; it has an input compensator for energy optimization, working sections with "zero-leak" check valves, and is widely configurable with manual proportional controls, hydraulic, electrohydraulic proportional controls, including the new electronic module CAN bus NG5.

This new proportional electrohydraulic control NG5 is also used on the section of the DPK120 dedicated to Hitch Control, replacing the manual adjustment with efficient and precise management of all machine implementations.

The new Hitch Control section managed via CAN bus supports the PWM version already available on the SD8 valve, by expanding the solutions available for the control of agricultural machinery.