At bauma and eima 2022, the evolution of Walvoil ALS – Adaptive Load Sensing System

Energy Sustainability on mobile machines with the new Hydraulic Digital Solution product line

After the ALS - Adaptive Load Sensing system, tested in collaboration with the manufacturer of telehandlers Dieci, won the technical novelties award eima 2020-21, Walvoil presents at bauma and eima international 2022 the evolution of the system, part of the new Hydraulic Digital Solution product line.

The modern mobile machinery market demands a constant increase in productivity and performance, together with lower operating costs, greater efficiency and reduced emissions in favour of sustainability and social responsibility.

Walvoil pursues these goals by reducing consumption and energy dissipation with its ALS (Adaptive Load Sensing) systems.

The studies conducted and the application of ALS to various types of vehicles demonstrate energy savings of up to 5%.

The ALS Solution

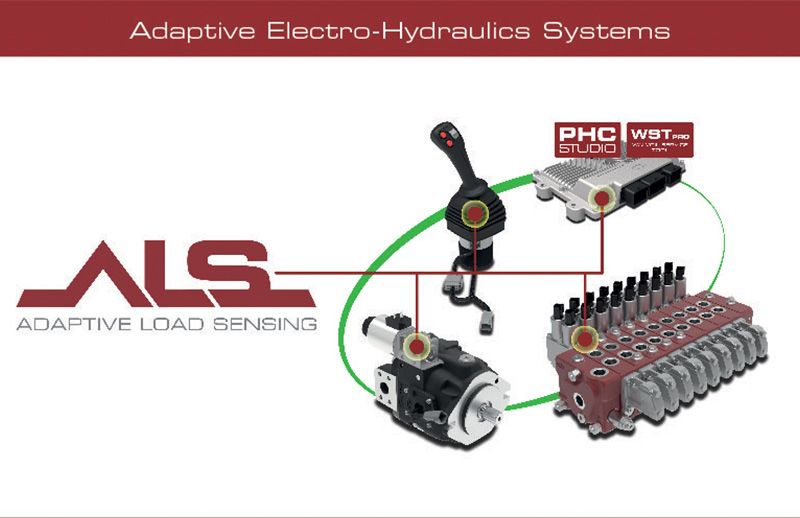

ALS is a synergistic set of components for the efficiency of mobile operating machines.

The joint control of the hydraulic directional control valve and the pump makes it possible to cut down pressure drops due to the pressure margins of the metering system. At the same time, a series of logics are available to improve machine control, productivity, and driving comfort.

Walvoil offers different ALS solutions to provide extreme versatility and adapt to the performance and system requirements of the machine.

In fact, the ALS system can be used as an integral part of the hydraulic directional control valve or fitted to the variable displacement pump.

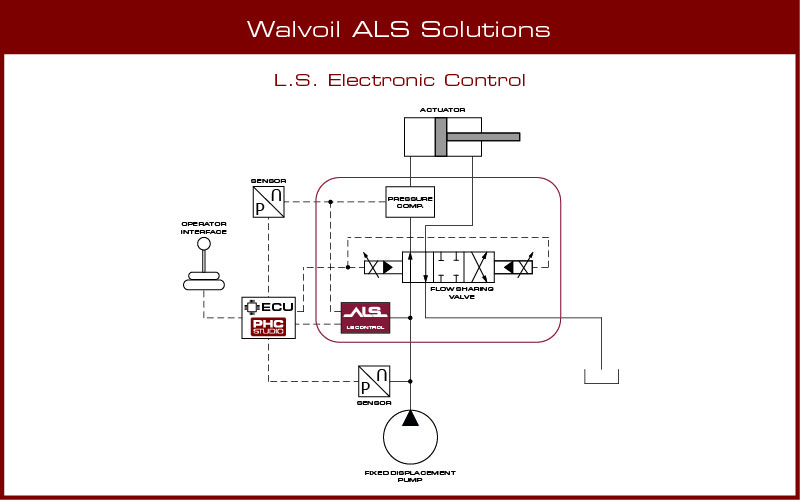

ALS – LS Electronic Control

Questa soluzione consente la realizzazione di funzioni Pressure Control in abbinamento a distributori Flow This solution enables to use Pressure Control functions paired with Flow Sharing directional control valves of the DPX and EPX series. The system manages and conditions the Load Sensing signal of the circuit in order to reduce consumption and optimize control.

Since the ALS system can be fitted directly to the directional control valve, its benefits can also be enjoyed combined with fixed displacement pumps.

When using variable displacement pumps, the ALS system further expands its energy-saving and controllability capabilities by managing the electronic control of the pump itself.

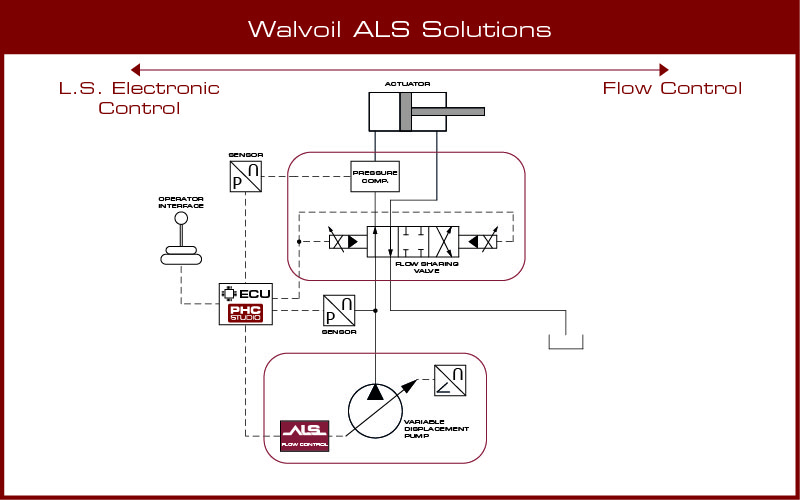

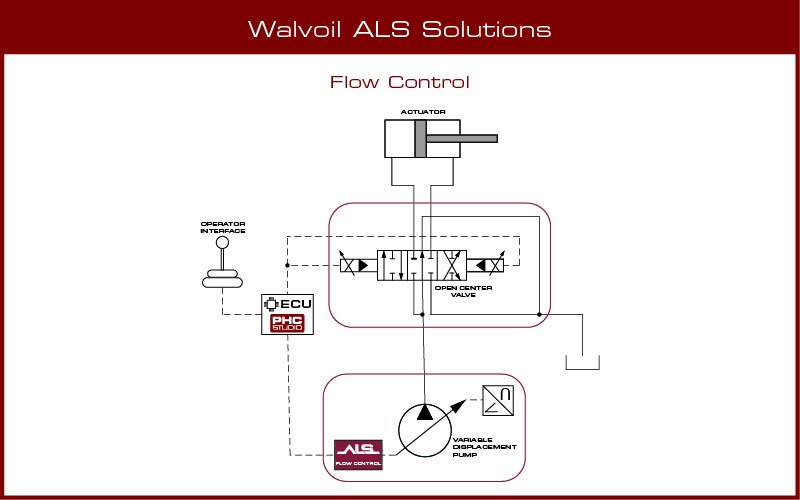

ALS – Flow Control

The special feature of this configuration is the combination of a normal electro-proportional Open Center directional control valve with the electronically controlled variable displacement pump equipped with ALS logic.

The Variable displacement pump supplies the flow demand settled by the operator logic (dedicated software), accordingly with single or multiple operations

In this configuration the Flow Control Logic ensures better load metering and greater vehicle stability combined with a tangible reduction in fuel consumption.

The system is managed by an electronic control unit and a specially developed software in the PHC STUDIO environment.

The main benefits of the ALS system are:

• Pressure Margin reduction both during operation and machine inactivity phases

• Definition of easily customizable control and sensitivity curves using PHC STUDIO software

• Definition of different operating conditions for maximizing control or productivity

• Dynamic torque and power limitation

• Greater utilization of installed power

• Less fluid heating

• Less instability and oscillations

• Customizable actuation modes for more comfortable driving.

The ALS is also provided standard with some basic functions.

Precision function: reduces the Pressure Margin value, allowing to improve the accuracy and sensitivity of operation.

Boost function: temporarily increases the Pressure Margin value for higher speeds and productivity, without the need to install larger pumps.

ALS + EPX: a winning combination

ALS and EPX are two highly flexible technologies that can be combined and add up to their respective benefits.

Variety of configurations and strong electronic integration allow solutions to be adapted to a wide variety of circuit configurations. Different levels of complexity and performance can be achieved thanks to the modularity of the PHC STUDIO software.

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS