NEWS

"HYDRAULIC DIGITAL SOLUTIONS", THE NEW FRONTIER OF RESEARCH IN FLUID POWER AND MECHATRONICS

Is hydraulics really at the end of its life cycle? To those who argue this in the light of the advancement of electrification not only in automotive, but also in mobile applications, Walvoil responds with its investments in production sites and technologies, and in a R&D that believes in increasing reliability through the study of alternative materials and processes and in energy efficiency, which is still one of the main drivers of development in the Fluid Power world.

We respond through our new Hydraulic Digital Solutions, products and systems that increasingly focus on efficiency, savings and energy recovery, such as ALS and EPX; solutions for which evolved components are able to offer the best in terms of increased functionality and energy efficiency strategies thanks to ECUs (electronic control units) and proprietary software which contribute to the construction of true mechatronic systems.

Innovative solutions such as Adaptive Load Sensing (ALS) and EPX technology, which together provide up to 25% reduction in consumption.

NEWS

ALS - ADAPTIVE LOAD SENSING: THE CONTRIBUTION TO ENERGY SAVING AND INTEGRATION WITH OTHER HYDRAULIC DIGITAL SOLUTIONS

Part of the new Hydraulic Digital Solutions product line, the ALS received the EIMA 2020-21 Technical Innovation Award, and has since continued to gain market acclaim.

The ALS, whose tests in cooperation with telehandler manufacturer Dieci confirmed a reduction in energy consumption of more than 5-6%, can be used as an integral part of the hydraulic directional valve or inserted on the variable displacement pump.

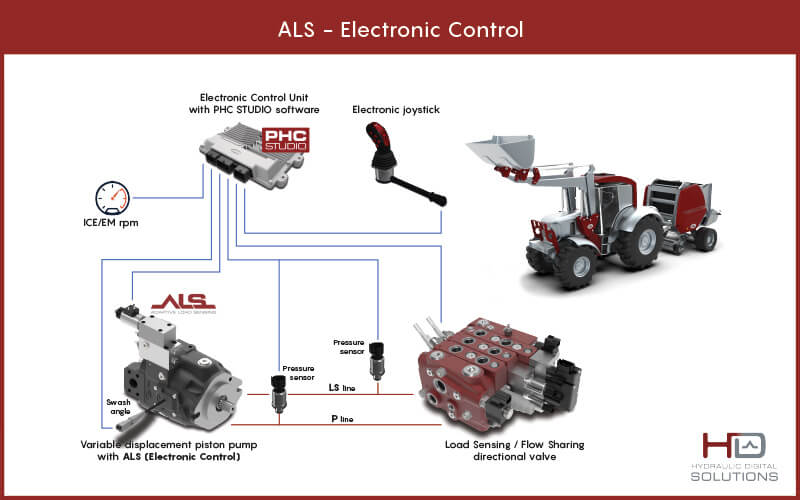

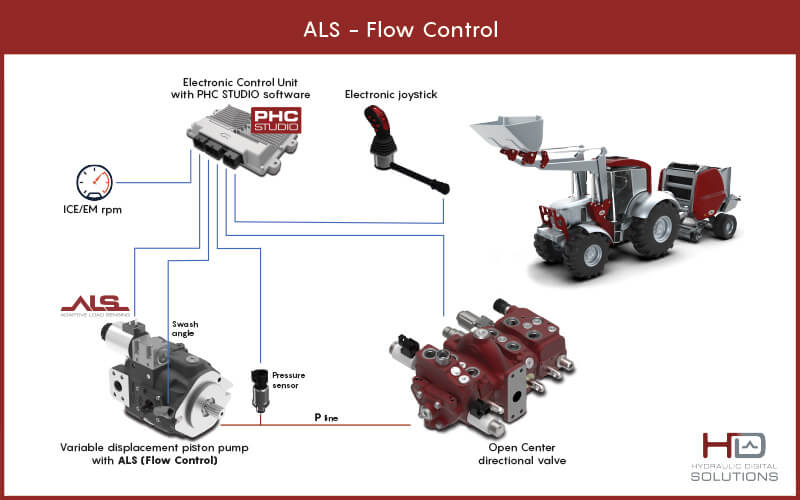

To offer extreme versatility and adapt to the machine's performance and system requirements, Walvoil offers the system in three different circuit solutions.

The ALS, which has also already been tested in conjunction with EPX technology, enables new levels of performance in the agricultural sector and reduced fuel consumption thanksto the Electronic and Flow Control logics integrated into the DPK120 tractor solution with Hitch Control.

Read all…

NEWS

AT AGRITECHNICA 2023 THE HYDRAULIC ENERGY RECOVERY: THE EVOLUTION OF WALVOIL'S EPX TECHNOLOGY

More and more manufacturers are moving their agricultural machinery towards electrification to reduce emissions and generate green energy.

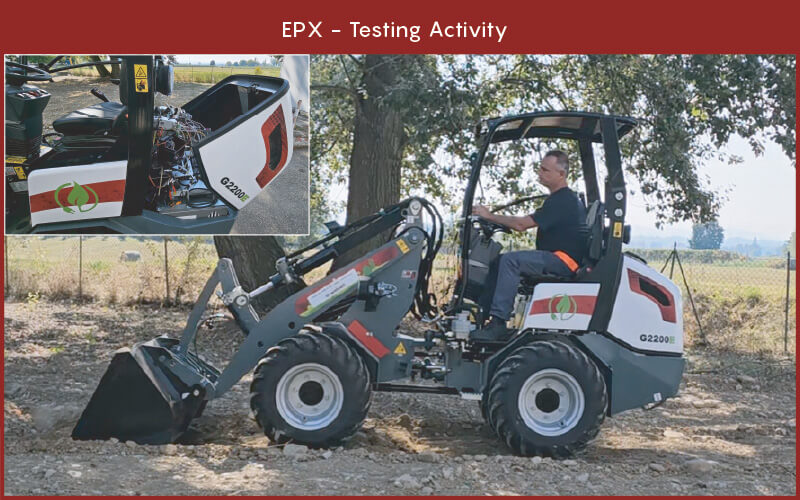

To advance this technological development, Walvoil promotes the new EPX Technology.

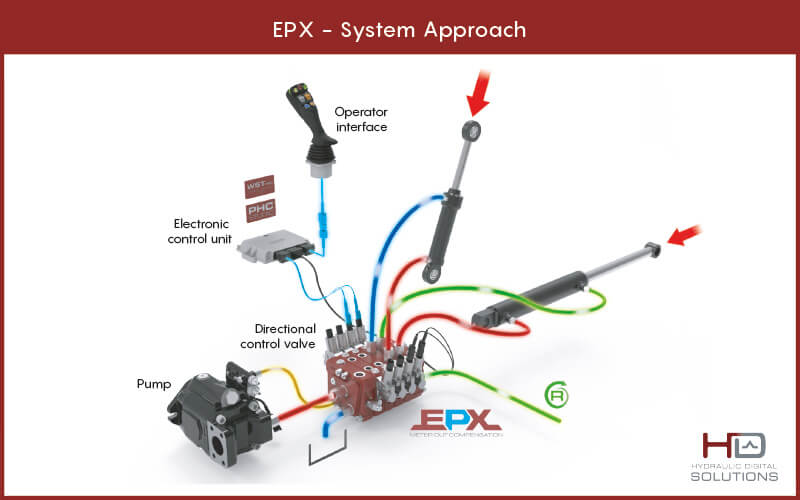

This new Flow Sharing directional valves series, based on meter-out compensation technology and an integral part of Walvoil's Hydraulic Digital Solutions, allows the management and recovery of the hydraulic energy consumed during simultaneous movements of several functions or with inertial loads. Energy that can be re-imported into the system in several ways.

This solution is very suitable for applications such as front loaders or compact wheel loaders, allowing to reduce consumption and return a part of energy, with an overall energy saving that, depending on the type of application, can reach 20%.

Read all…

NEWS

HYDRAULIC DIGITAL SOLUTIONS FOR TRACTOR AND IMPLEMENTS

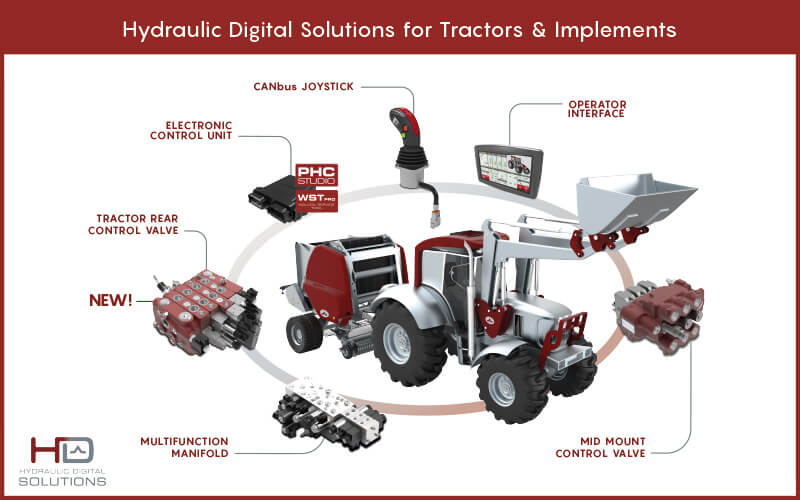

It is a true modular system, what Walvoil's Hydraulic Digital Solutions enable to offer a tractor application in line with the requirements of the most sophisticated and modern technologies on the agricultural market today.

The Walvoil solution includes the new DKP120 sectional valve, the CAN bus NG5 electronic module and the Hitch control valve.

The DPK120 is a pre-compensated sectional valve for open/closed centre circuits, specifically designed for tractors and front loaders with flow rates up to 120l/min.Thanks to its flexibility and wide configurability, this new sectional valve is compatible with all Walvoil products, so it provides complete solutions that can meet all requirements in terms of performance and low consumption. The DPK120 is available with manual, proportional hydraulic and electrohydraulic controls.

The new NG5 module enables electrohydraulic CAN bus control of sliders quickly and accurately with integrated electronics (safety up to PLd/SIL) and contactless position sensor.

The integration of Hitch Control within a dedicated work section enables an automated system for controlling the machine's equipment, whether towed or pushed, replacing manual adjustment with more efficient and precise handling.

NEWS

WALVOIL: A NEW INNOVATION CENTER SERVING WALVOIL GROUP'S R&D ACTIVITIES WORLDWIDE

In time for Agritechnica, Walvoil will have its new Innovation Center located in the expanded area of Corte Tegge site (Cavriago, Reggio Emilia - Italy). The Corte Tegge site has now become the headquarters of Walvoil's R&D, Technical Offices and Electronics Design teams, and one of Walvoil's largest production and logistic hubs in Italy.

The new Innovation Center, together with the expanded plant hosting from now on also the Electronics Department and most of the activities dedicated to Hydraulics, have been built according to the most modern methods to ensure maximum efficiency and sustainability, both environmental and social.

The Innovation Center hosts the expanded R&D laboratories, formerly located in via Norvegia, 10, in Reggio Emilia, and dedicated to technological materials and vehicle testing, endurance and performance tests, special tests (environmental, vibration, acoustic, mechatronics) and others.

These laboratories, already the flagship of the Walvoil Group and the operational heart of all research activities, will be further of service to foreign branches in Australasia, Brazil, Canada, China, Korea, France, India and the United States.