ALS – Adaptive Load Sensing system at eima 2021: the system developed by Walvoil in partnership with Dieci exhibited in the area dedicated to tech news and rewarded as Technical Innovation

Walvoil’s and Dieci’s contribution to energy saving on agricultural machines

The ALS Adaptive Load Sensing system developed by Walvoil is a winner project of the Technical Innovation Contest Eima 2020-21, recognition of absolute innovation, also with the ‘Blue Award’ dedicated to the solutions that stand out in terms of environmental sustainability.

From 19 to 23 October this innovative system was exhibited in the innovation area of the fair fitted on an Agri Farmer 34.7 GD by Dieci, partner company with which all the experimental tests have been conducted.

The collaboration between the two global companies with Italian roots continues: Walvoil Spa, a historic brand in the Emilia-Romagna hydraulic sector part of the Interpump Group since 2015, and Dieci Srl, an important telehandler manufacturer since 1982.

Tested in 2020 on an Agri Plus 42.7 GD for participating in the eima competition, the ALS system confirms its effectiveness compared to a standard configuration also on the Agri Farmer 34.7 telehandler present at eima, a more compact and easier to handle machine.

What does ALS - Adaptive Load Sensing consist of?

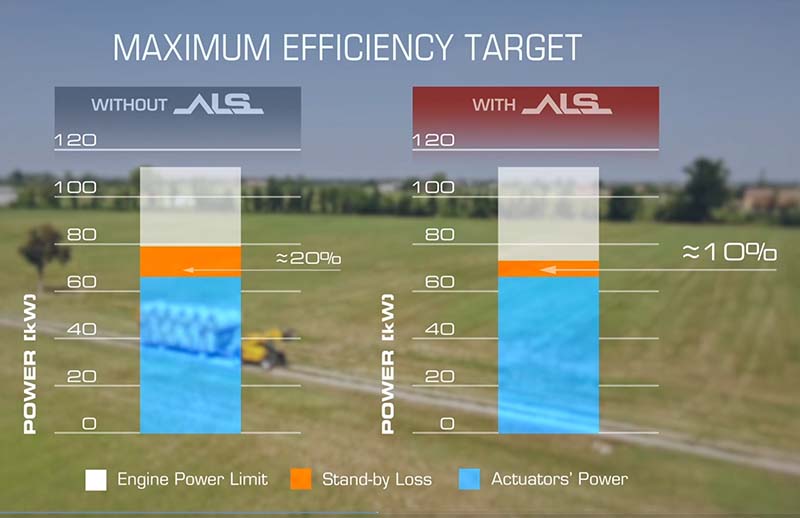

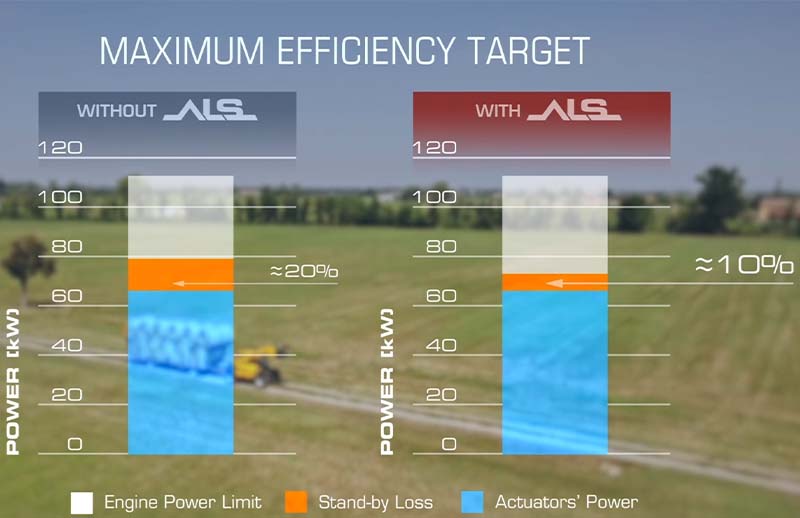

Hydraulic systems are an essential part of the most modern and widespread agricultural machinery, especially for telehandlers, which have now become irreplaceable for most companies. In order to ensure the simultaneous control of movements in these systems, the hydraulic pump generates a pressure higher than what is really necessary, a predetermined value called "Stand-by pressure differential" which has been considered acceptable until now, but which implies a considerable loss of energy, limiting the overall performance of the vehicle and unnecessarily increasing wear and consumption, to the detriment of efficiency and environmental impact.

The ALS system is able to modulate the "Stand-by pressure" value according to the real working needs of the machine, automatically varying it only when and as required.

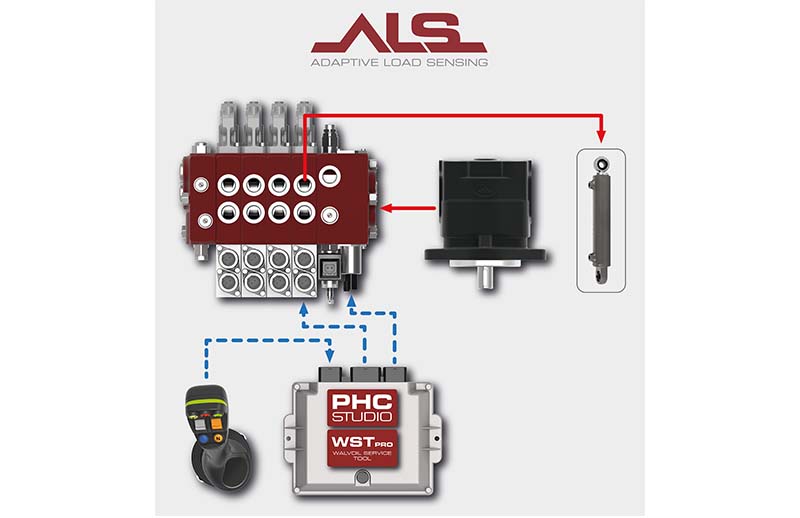

The Electronic Control Unit collects information from the operator and from the machine sensors. It operates the Adaptive Load Sensing device, allowing to raise or to lower the Load Sensing hydraulic signal and consequently varying the pressure differential to dynamically adjust it to the efficiency and functionality requirements of the vehicle.

The heart of Adaptive Load Sensing is represented by an electro-hydraulic device fitted on the directional control valve, which allows to dynamically modulate the Stand-by Margin, in order to minimize wear and energy consumption.

The Agri Farmer 34.7 GD, a more compact and lightweight machine than the Agri Plus used in 2020, is equipped with a single fixed displacement pump and, compared to the previously tested model, benefits even more from the advantages offered by the ALS system.

In particular, the ALS system allows to significantly lower the stand-by pressure differential, ensuring high efficiency and significant energy savings, even in contexts of a simple and essential hydraulic circuit. The energy benefits are especially noticeable when the machine is stationary and when moving at high speed.

In the auxiliary drive, the careful stand-by management of the Load Sensing DPX circuit combines energy saving with increased controllability and movement precision.

An accurate tuning activity on the Agri Farmer 34.7 GD ALS carried out at Walvoil Test Department, allowed to optimize the control software and implement it with numerous new features. In particular, in addition to the actions aimed at limiting consumption, it was possible to emphasize the effect of the Boost and Precision operating modes and, with an appropriate customization of the stand-by, some effects of instability and jolt were eliminated, ensuring a better comfort for the operator.

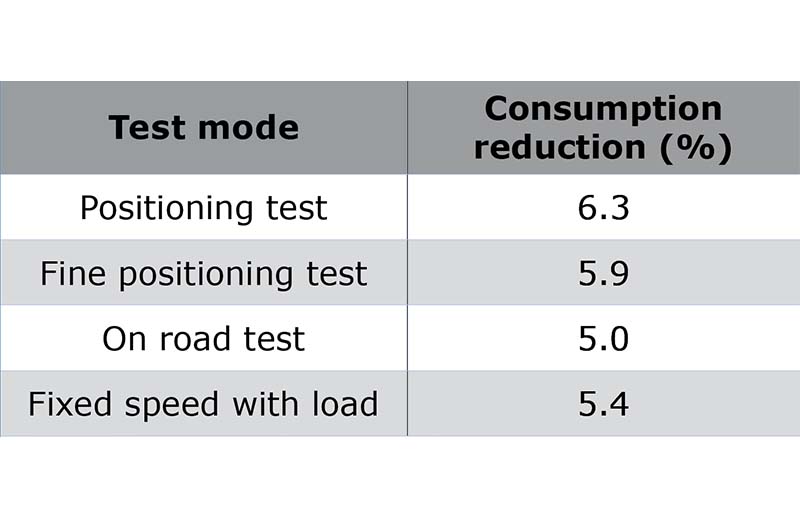

Finally, the results of the joint testing activity were collected, on the Dieci Research Centre track, by carrying out four characterizing tests aimed at evaluating the consumption of a predefined cycle, the efficiency of precision positioning and consumption in two transfer modes.

Through all tests, the Agri Farmer 34.7 GD, equipped with the ALS system, showed a consumption reduction between 5% and 6% compared to the same model without ALS, confirming and improving the preliminary results obtained in 2020 on an Agri Plus 42.7 GD VS EV02: a drop in energy dispersion value equal to 28% during boom operations, a drop up to 45% during traveling phases.

In addition, in the positioning accuracy test, a higher productivity of the machine was clearly noticeable; the improved controllability of the Precision function in fact allowed 14% more operating cycles in the same amount of time.

This last testing phase has highlighted further important advantages, first of all in terms of Safety, Stability, Flexibility and Modernization: the few elements of the ALS kit can, in fact, be easily installed even on older telehandlers, extending their operating life and improving their performance.

These are all important results of an excellent collaboration between companies with a vision of the future: an experience that opens the way to new ideas and opportunities for improving the efficiency of mobile machinery, increasingly necessary in this historical moment, in which each of us is required to do our part to preserve the planet that hosts us.

The development of the ALS system also benefits from the collaboration of TASC, "Smart and Clean Agricultural Tractors Project", a project that includes the participation of the main university research laboratories of the Emilia Romagna Region, created with the aim of minimizing the environmental impact of agricultural mechanization.

Captions:

- Agri Farmer 34.7 GD Dieci equipped with Walvoil ALS – Adaptive Load Sensing system

- Walvoil ALS system

- ALS on Agri Farmer 34.7 GD Dieci at eima 2021

- Awards received by Walvoil and Dieci during the Gala Dinner held on October 22 at Palazzo Re Enzo, Bologna – Italy. Davide Mesturini – Walvoil R&D Director on the left, Enrico Ognibene – Dieci R&D Director on the right

- Max. efficiency target: with the ALS system it is possible to manipulate the stand-by margin, obtaining an energy benefit for the same operation

- Test modes and consumption reduction (%) confirmed

Walvoil Communication & Marketing

walvoil@walvoil.com

Tel. 0039.0522.932411

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS