Energy Sustainability on operating machines

The modern mobile machinery market demands a constant increase in productivity and performance, together with lower operating costs, greater efficiency and reduced emissions in favor of sustainability and social responsibility.

Various research and studies in the field point out that up to 40 % of the energy supplied to the hydraulic system of the operating machine is dissipated by the limited efficiency of the components and the pressure drops due to the metering and control of the movements.

The problem is even more evident on electrified applications, where energy efficiency is synonymous with prolonged range and reduced battery capacity.

Walvoil illustrates how to aim for increased efficiency of the hydraulic system and its components, with a possibility of reducing consumption by more than 20%.

Walvoil pursues this goal by acting in 2 ways:

- by reducing consumption and energy dissipation with ALS (Adaptive Load Sensing) systems.

- by recovering energy, which would otherwise be wasted, through EPX (Meter out compensation) technology.

(pic. 1) (pic. 2)

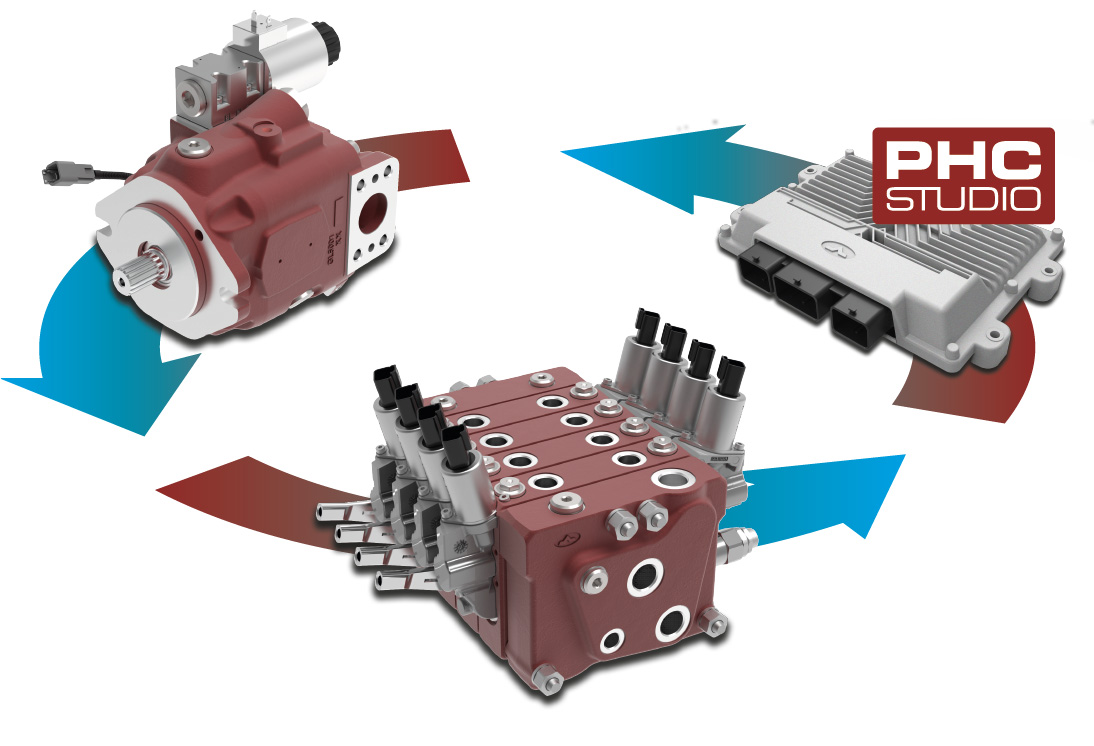

Energy efficiency is achieved through a system approach and strong electronic integration, aiming at the interconnection and coordination of specially designed components: pump, directional control valve, electronic control unit, and operator interface.

The ALS solution

ALS is a synergistic set of components for the efficiency of mobile operating machines.

The joint control of the hydraulic directional control valve and the pump makes it possible to cut down pressure drops due to the pressure margins of the metering system. At the same time, a series of logics are available to improve machine control, productivity, and driving comfort.

Walvoil offers different ALS solutions to provide extreme versatility and adapt to the performance and system requirements of the machine.

In fact, the ALS system can be used as an integral part of the hydraulic directional control valve or fitted to the variable displacement pump.

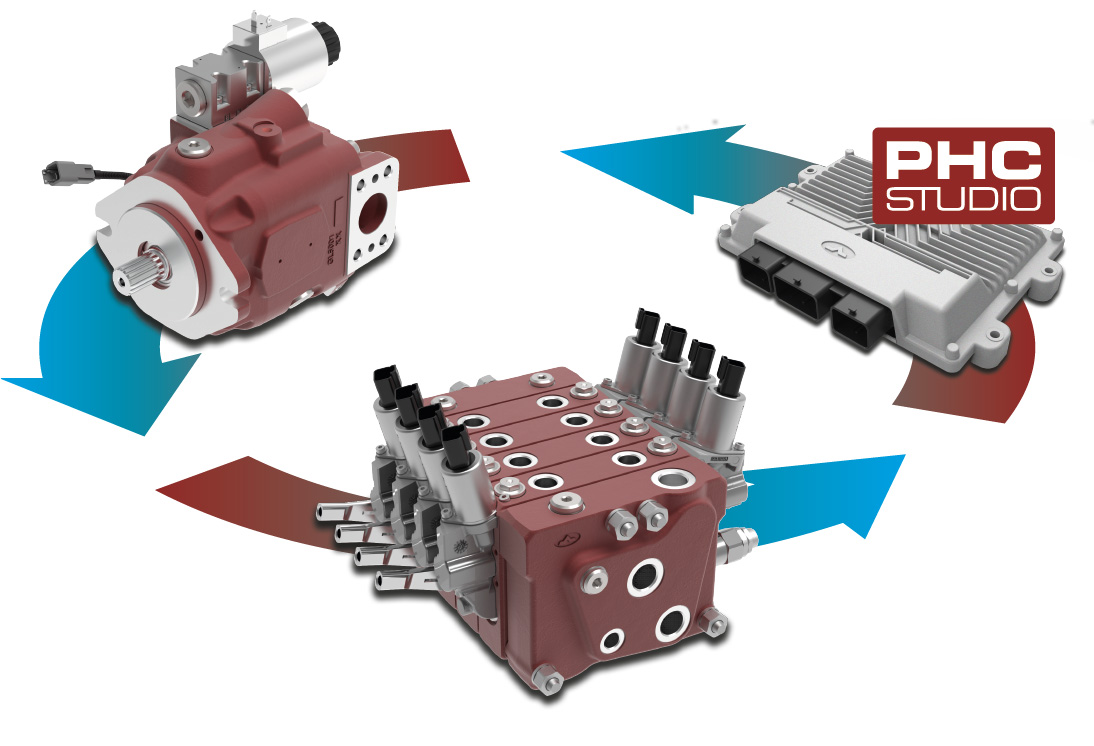

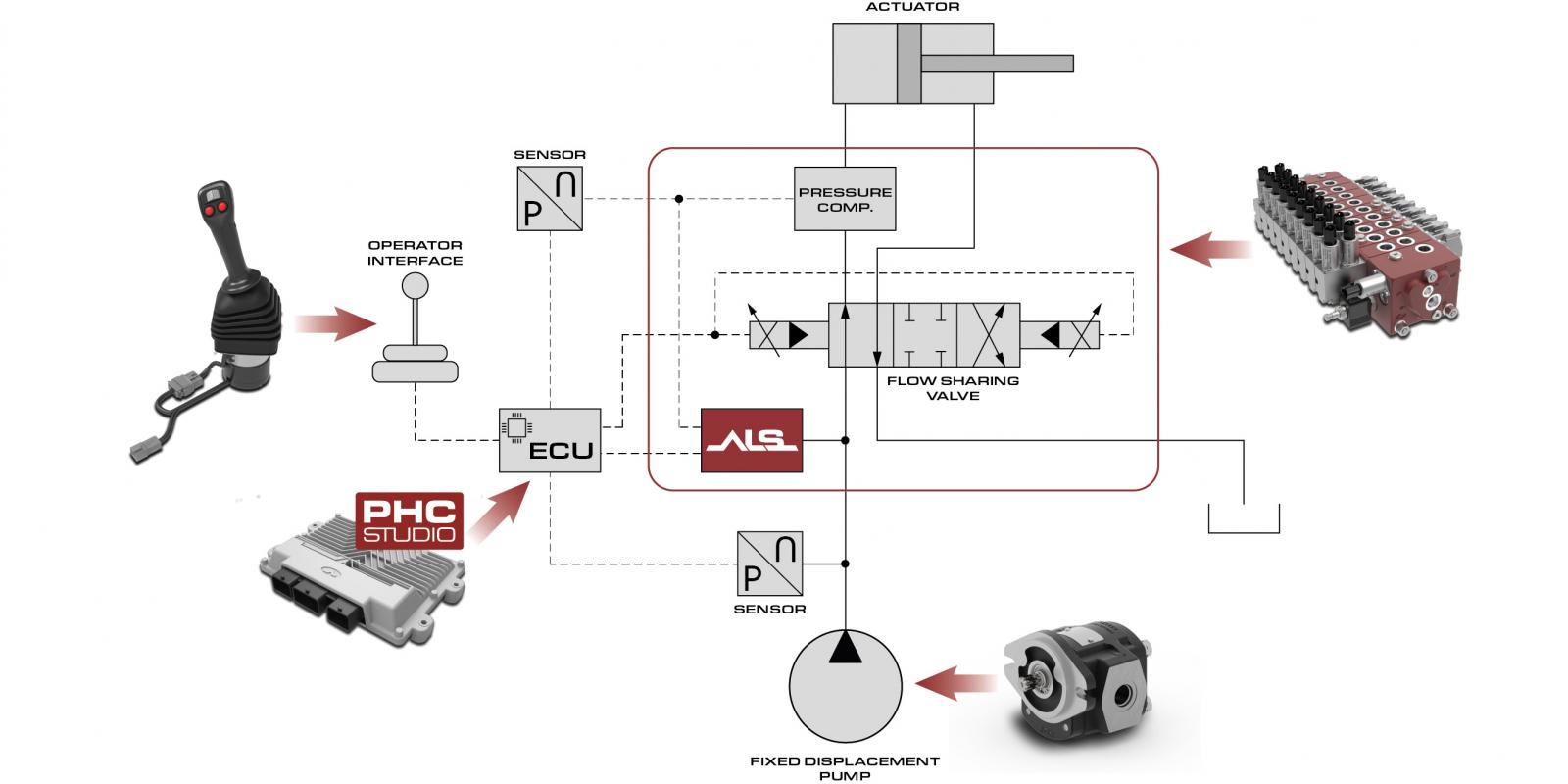

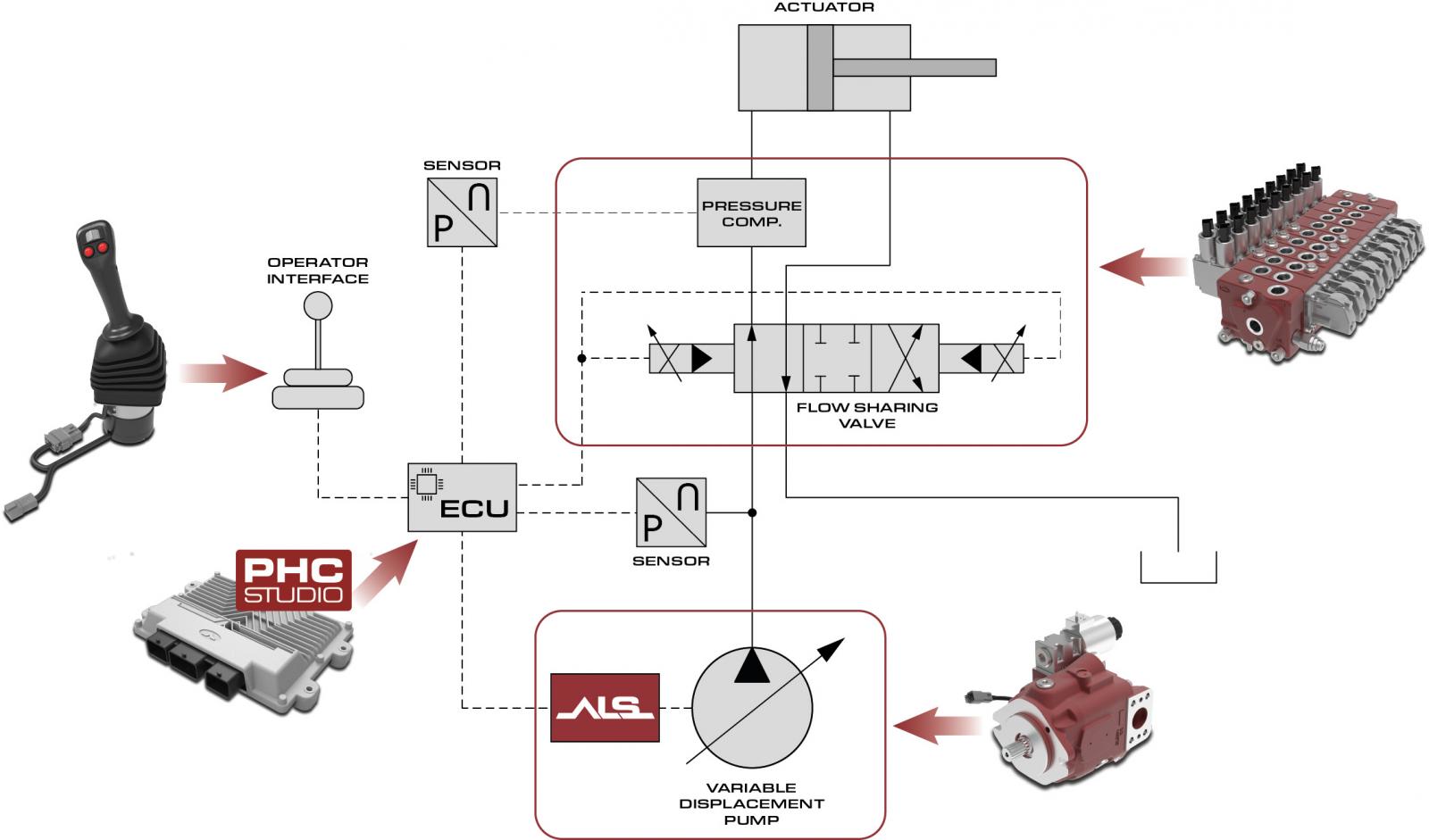

ALS – Electronic Flow Sharing

This solution enables to use Pressure Control functions paired with Flow Sharing directional control valves of the DPX and EPX series. The system manages and conditions the Load Sensing signal of the circuit in order to reduce consumption and optimize control.

Since the ALS system can be fitted directly to the directional control valve, its benefits can also be enjoyed combined with fixed displacement pumps.

(pic. 3)

When using variable displacement pumps, the ALS system further expands its energy-saving and controllability capabilities by managing the electronic control of the pump itself.

(pic. 4)

The system is managed by an electronic control unit and a specially developed software in the PHC STUDIO environment.

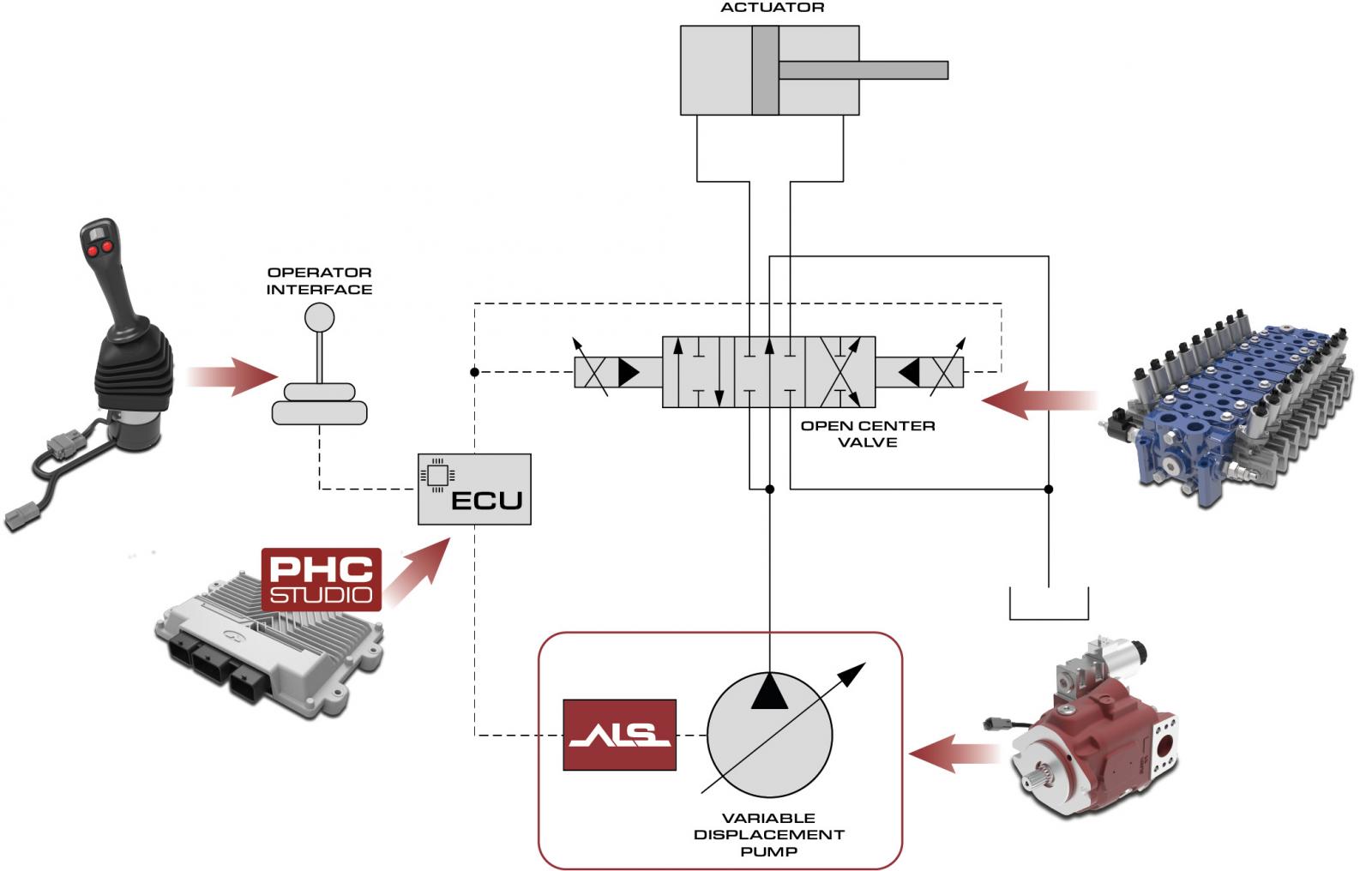

ALS – Flow on Demand

The special feature of this configuration is the combination of a normal electro-proportional Open Center directional control valve with the electronically controlled variable displacement pump equipped with ALS logic. The Variable displacement pump supplies the flow demand settled by the operator logic (dedicated software), accordingly with single or multiple operations

In this configuration the Flow on Demand Logic ensures better load metering and greater vehicle stability combined with a tangible reduction in fuel consumption.

The system is managed by an electronic control unit and a specially developed software in the PHC STUDIO environment.

(pic. 5)

Features and operational functions of ALS

The main benefits of the ALS system are:

• Pressure Margin reduction both during operation and machine inactivity phases

• Definition of easily customizable control and sensitivity curves using PHC STUDIO software

• Definition of different operating conditions for maximizing control or productivity

• Dynamic torque and power limitation

• Greater utilization of installed power

• Less fluid heating

• Less instability and oscillations

• Customizable actuation modes for more comfortable driving.

The ALS is also provided standard with some basic functions.

Precision function: reduces the Pressure Margin value, allowing to improve the accuracy and sensitivity of operation.

Boost function: temporarily increases the Pressure Margin value for higher speeds and productivity, without the need to install larger pumps.

EPX technology

EPX Series directional control valves are a new range of electro-proportional valves designed to enable the management and recovery of hydraulic energy in mobile machines.

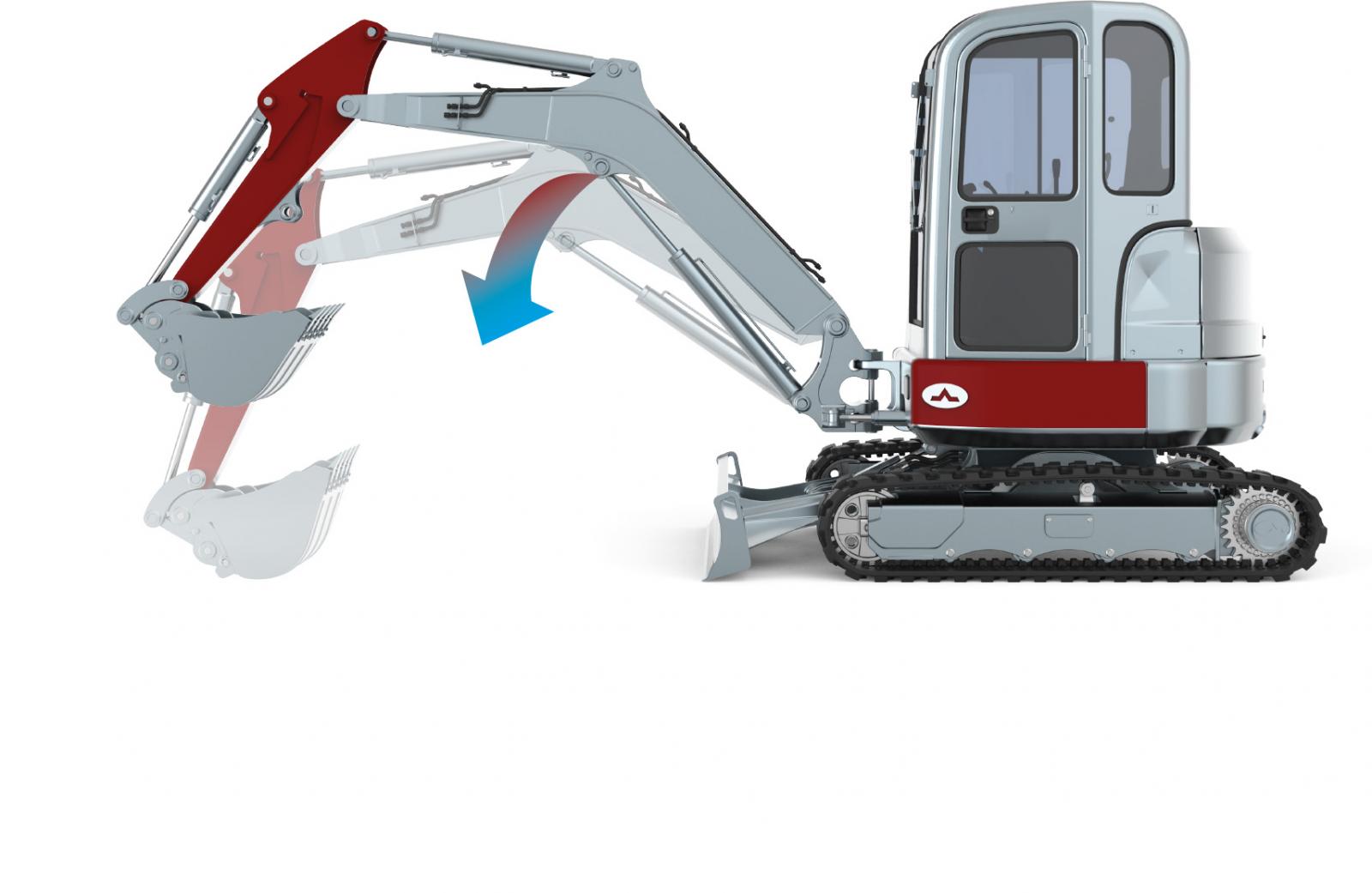

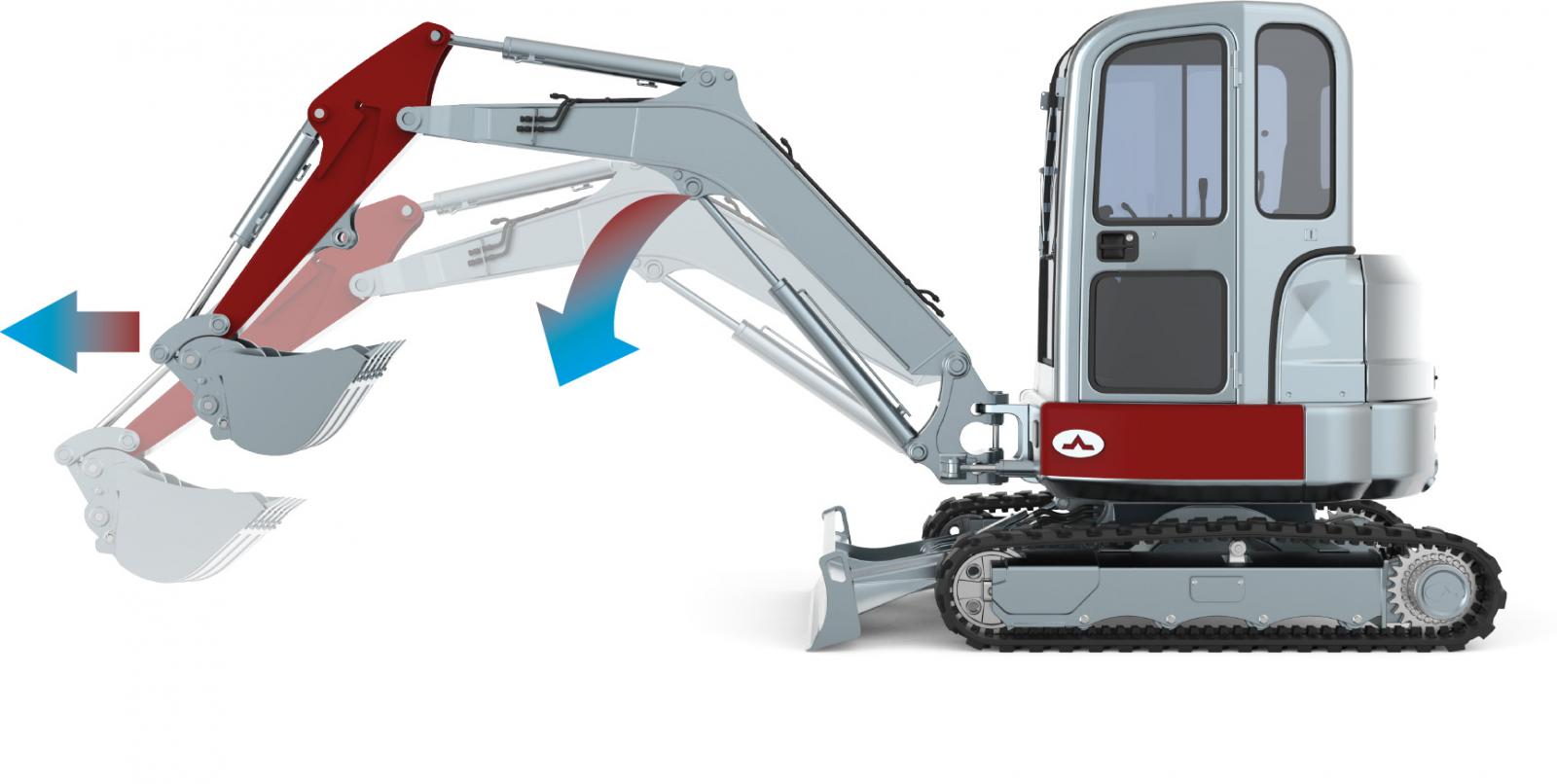

Recovery is achieved by a specially designed compensator acting in 2 ways:

- by implementing an active-type recovery during simultaneous operations of multiple machine functions

- by providing passive-type recovery due to drag loads, i.e., by reusing inertial energy that is usually lost through fluid lamination to tank.

(pic. 6) (pic. 7)

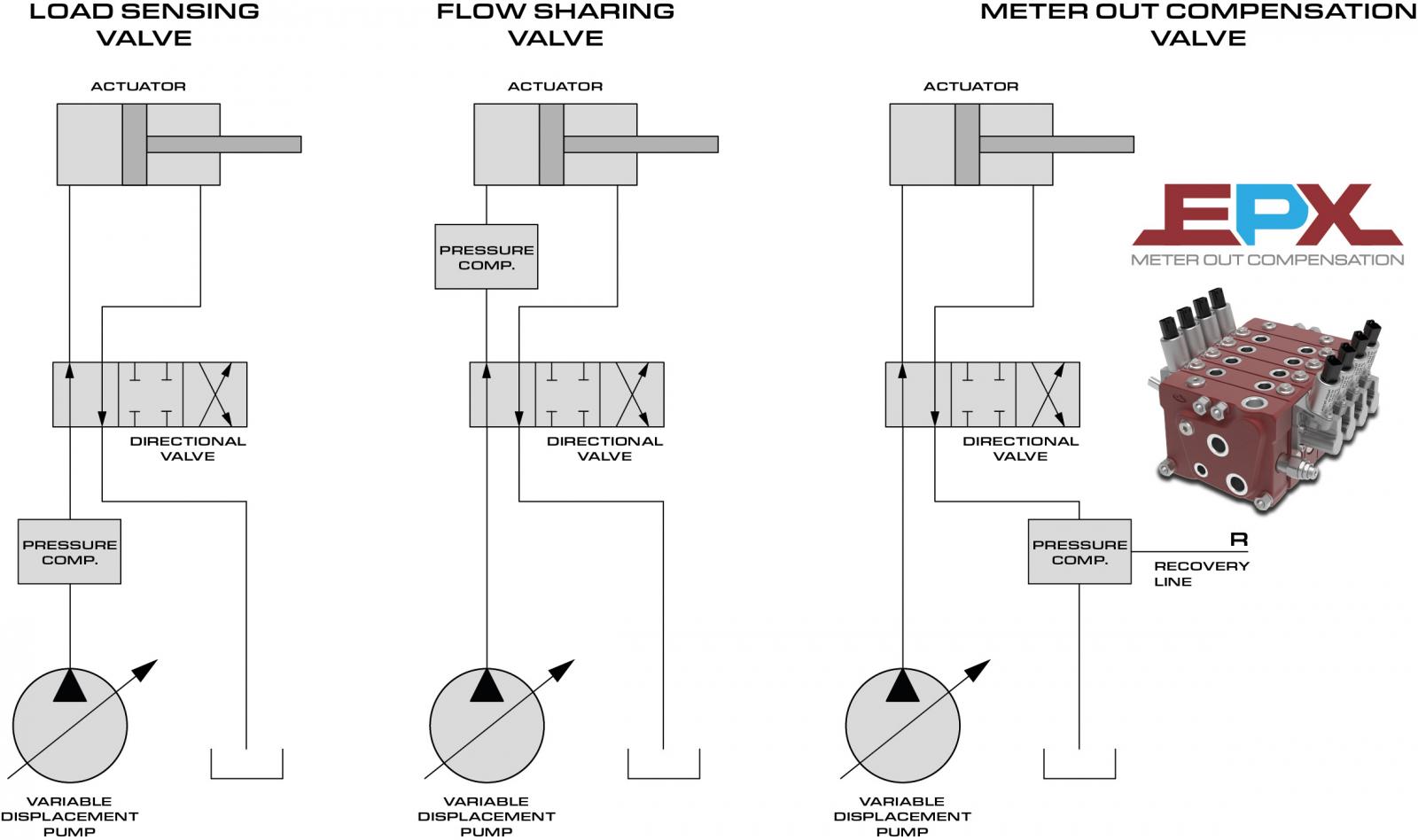

The example diagrams below show the circuit difference between a Load Sensing (pre-compensated) system, a Flow Sharing (post-compensated) system, and EPX (Meter out compensation) technology.

(pic. 8)

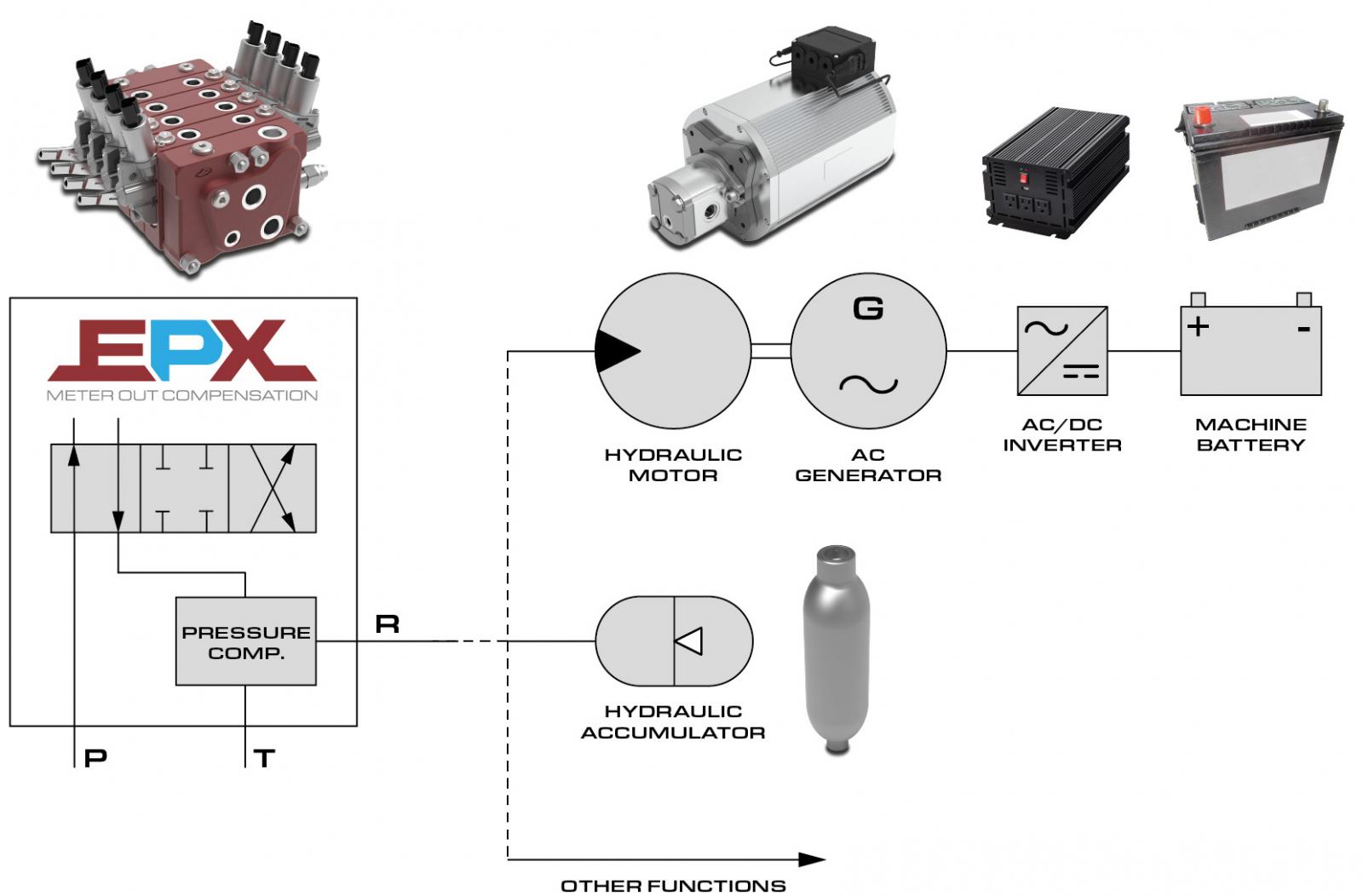

With the energy recovered through an EPX Series directional control valve it is possible to:

- Charge a battery set through a hydraulic motor connected to an alternator+inverter

- Make it available in the hydraulic system for reuse by machine functions

- Store it in hydraulic accumulators.

(pic. 9)

The EXP technology was the subject of a paper entitled 'Viable Energy Recovery Strategies through advanced Directional Control Valve' presented at the 13th International Fluid Power Conference (IFK) of Aachen in June 2022 and its evolution will be illustrated on the occasion of the 2022 IEEE Global Fluid Power Society PhD Symposium, to be held in Naples in October.

ALS + EPX: a winning combination

(pic.1) (pic. 2)

Two highly flexible technologies that can be combined and add up to their respective benefits.

Variety of configurations and strong electronic integration allow solutions to be adapted to a wide variety of circuit configurations. Different levels of complexity and performance can be achieved thanks to the modularity of the PHC STUDIO software.

The studies conducted and the application of ALS to various types of vehicles demonstrate energy savings of up to 5%.

Far broader is the potential for energy recovery of the EPX system, which is capable of lowering consumption and returning a share of energy, with overall energy savings of up to 20%, depending on the type of application.

Walvoil Communication & Marketing

walvoil@walvoil.com

Tel. 0039.0522.932411

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS