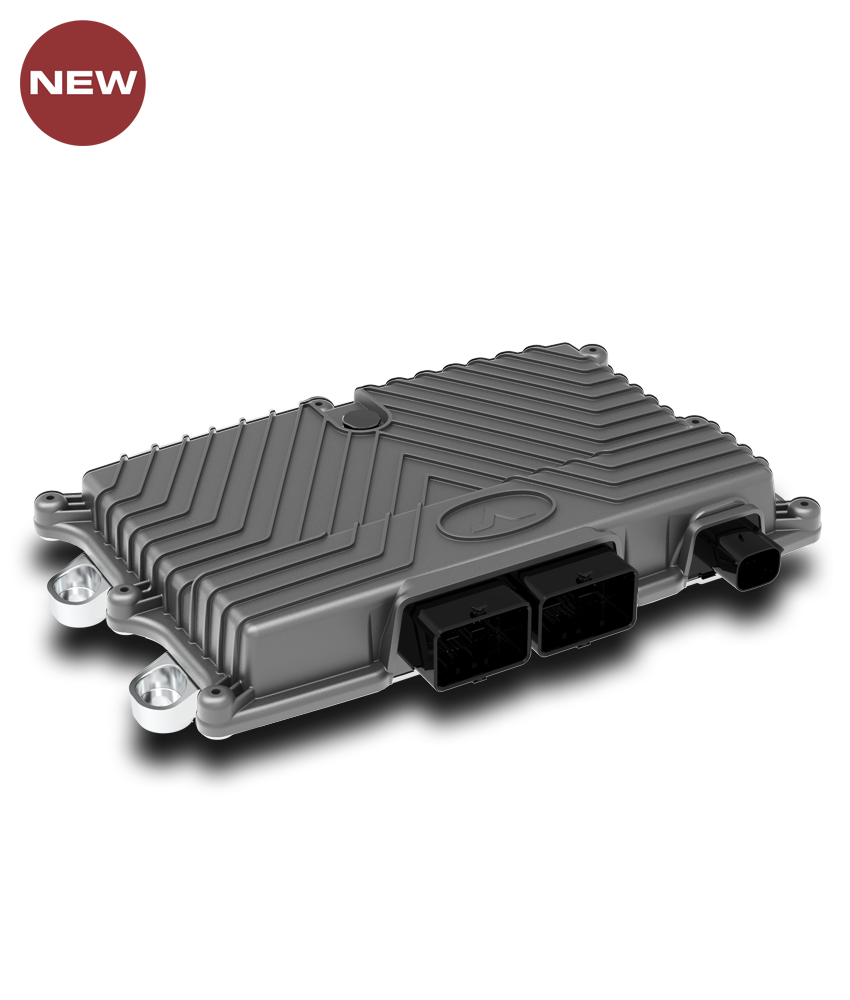

Electronic control units

The CED1200S is the first component of a new family of control units designed for safety related applications.

With Hardware Category 2, it can be used in applications up to Performance Level D / SIL 2.

It is programmable through Mathworks® tools.

This robust unit is completely sealed and protected against water and dust ingress (IP67/IPx9K).

All the PWM power outputs are available with current closed loop for applications with proportional pressure reducing valves.

The controller is suitable for 12V and 24V applications thanks to the 8 – 32V power supply input range.

There are 30 general purpose inputs (analog, digital, frequency, …), 4 CAN bus ports and a 5V sensors supply output.

The controller is qualified following the most rigorous international and customers standards.

Voltage supply: from 8 to 32 V

Maximum output current per pin: 2 A / 6 A

Number of proportional outputs: 6 @ 6A

Weather protection: IP67-IPx9K

Working temperature: from -40 to 85 °C (from -40 to 185 °F)

Storage temperature: from -40 to 85 °C (from -40 to 185 °F)

General purpose inputs: up to 30

Number of proportional sections controlled: 12 @ 2A

Number of relay outputs: 10

Maximum working temperature [°C]: 85

Maximum storage temperature[°C]: 85

Number of CANbus ports: 4

Number of 5V outputs: 1

Similar and complementary products

APPLICATIONS

AGRICULTURE

Machine integrated, efficiency and sustainability are the key words of Walvoil’s solutions and systems for agricultural machinery.

Read more…

CONSTRUCTION AND EARTH MOVING

High performance, energy saving and controllability are the main features of Walvoil’s integrated proposals dedicated construction and earth moving machines.

Read more…

MATERIAL HANDLING

Strength, precise and smooth movement control, compact hydraulics and operator’s comfort are our focus when we design our customers’ solutions.

Read more…

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS