WALVOIL SXP EVO: at bauma 2019 the innovative system developed for front loaders and other lifting applications.

Walvoil SXP EVO, evolution of the SXP directional valve already awarded as ‘technical news’ at Eima International 2018, is an innovative system developed for front loaders and other lifting applications, that will be introduced to the market at bauma 2019.

The main feature of new Walvoil SXP patented directional valve is the possibility to switch autonomously from Series Circuit to Parallel Circuit only by detecting the pressure of the circuit and managing this parameter together with the information set by the user.

The system increases the efficiency and productivity of the machine because the unconventional series circuit drastically reduces the cycle time; thanks to the uninterrupted switch to the parallel configuration, the maximun load capacity is granted and the operator doesn’t perceive any change in the control of the machine.

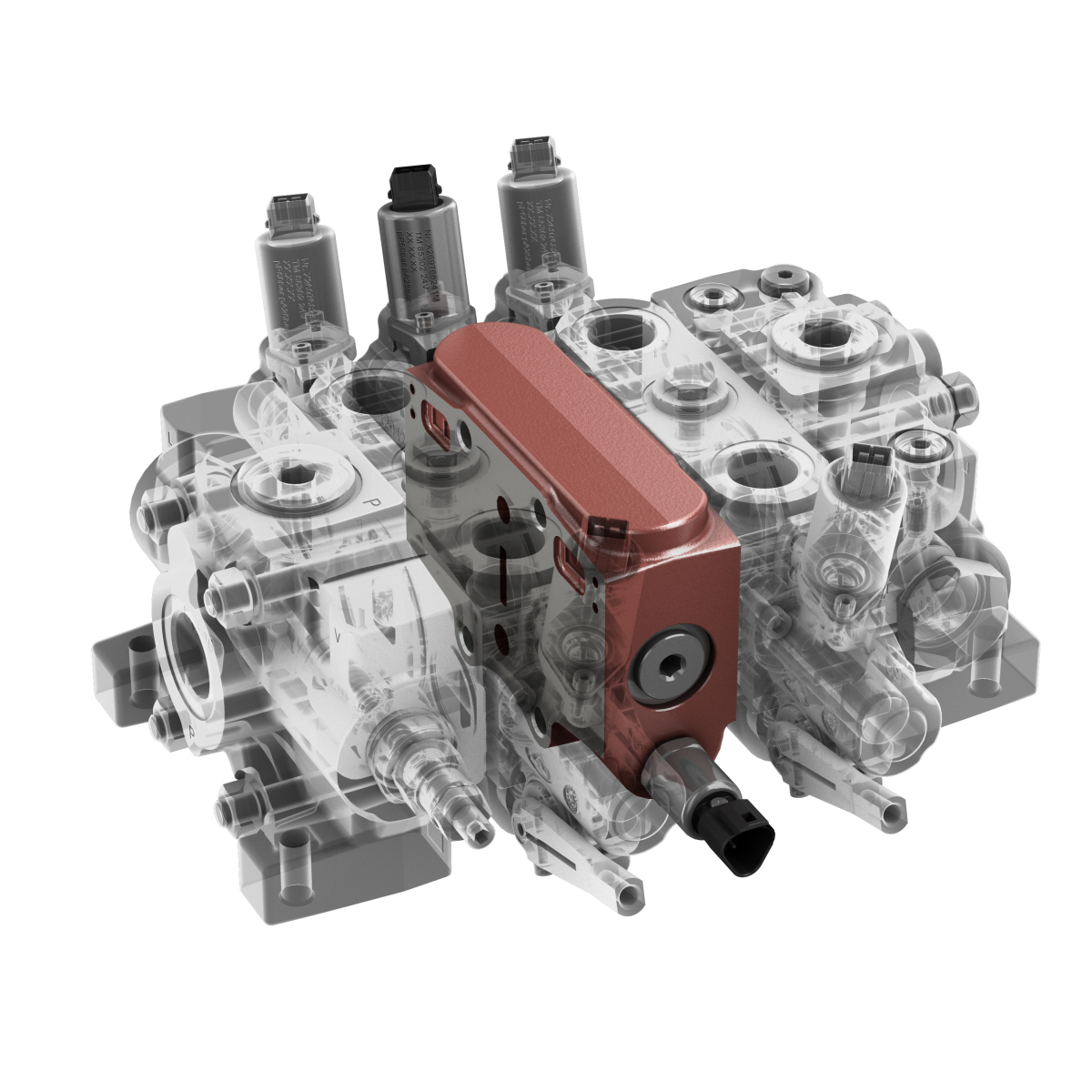

SXP EVO element composition

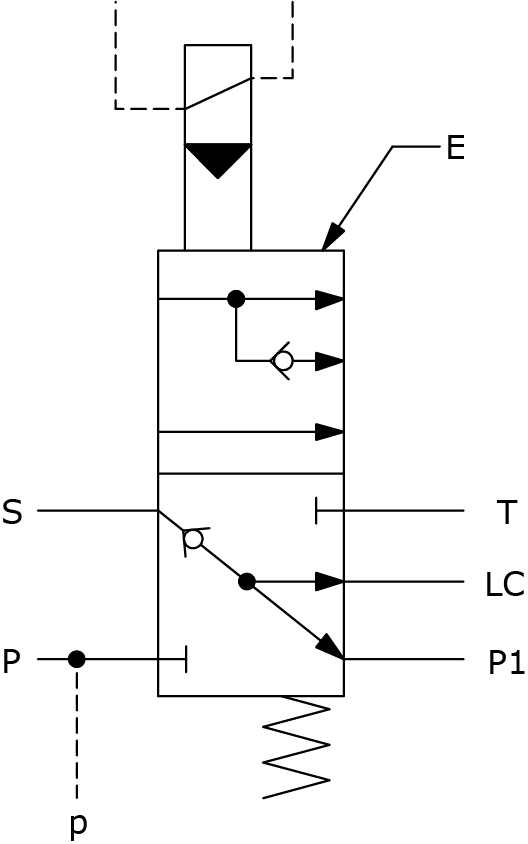

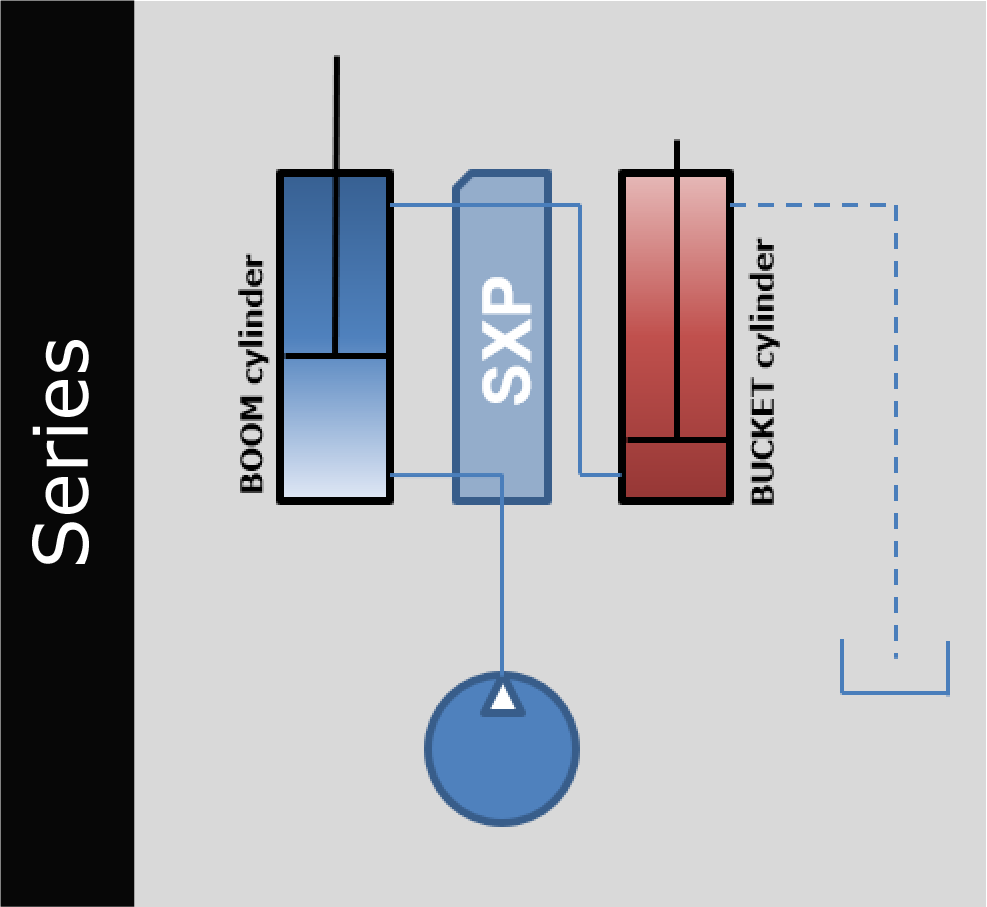

The SXP system consists of an E logic element positioned between the boom section and the bucket section of a directional valve.

In normal position the logic element (picture on the side) connects the return of the S Arm (ie series) with the supply of the Bucket called P1. At the same time the P pressure channel (ie paralell) is closed, as well as the tank connection through the T-port.

In this status the valve works as a normal SERIES circuit.

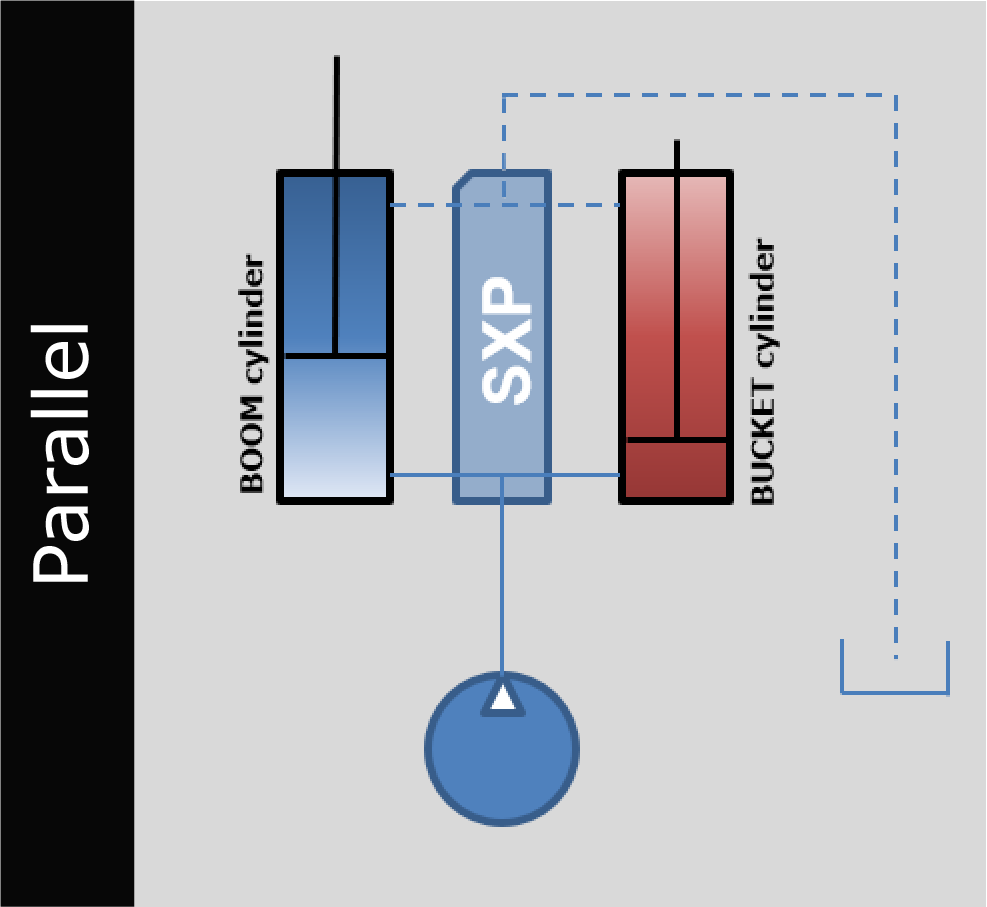

The E logic element also allows a second working position, connecting S channel to tank or returning it to free circulation and the simultaneous opening of the P parallel channel towards P1.

In this configuration the valve works as a typical PARALLEL circuit.

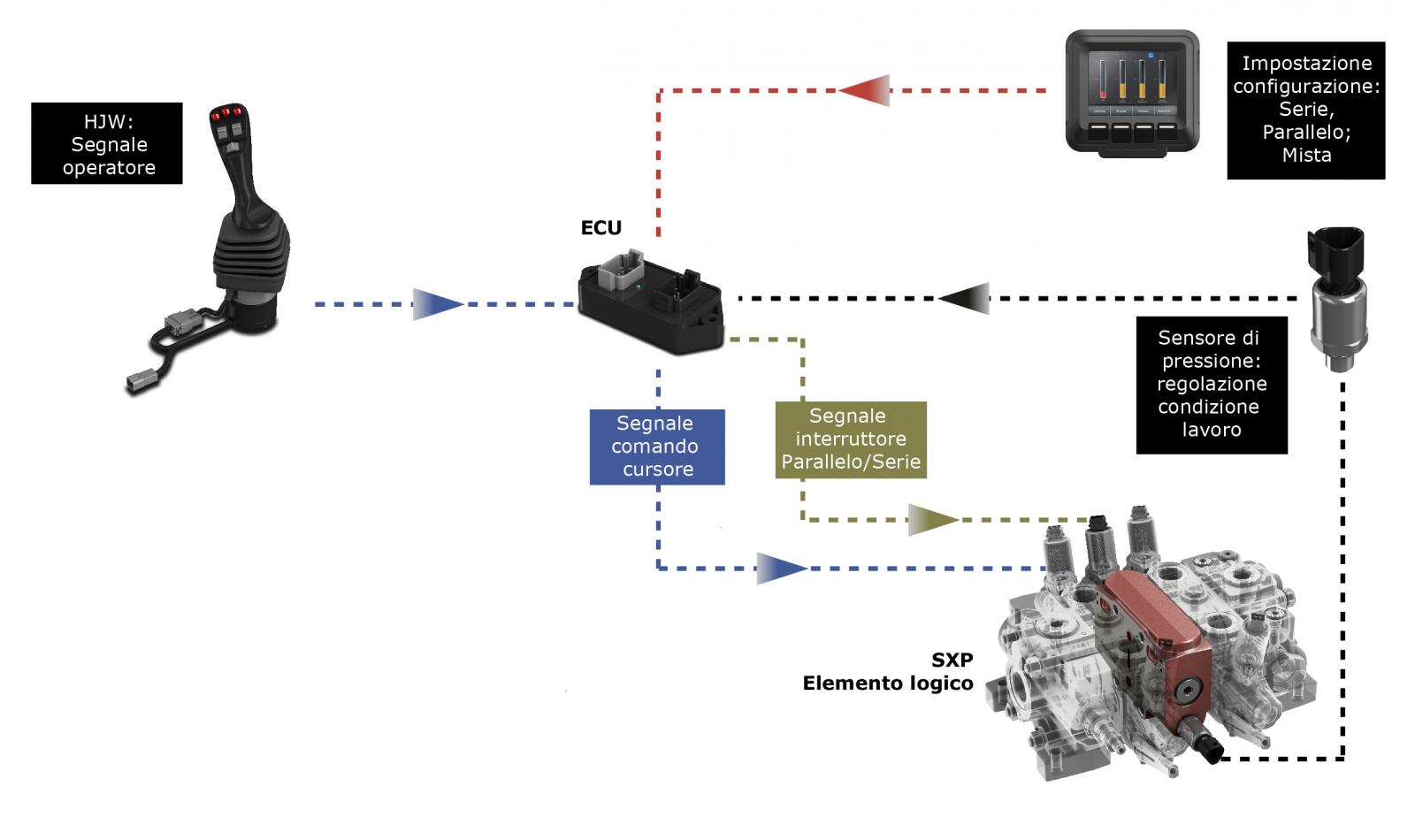

SXP EVO operating system

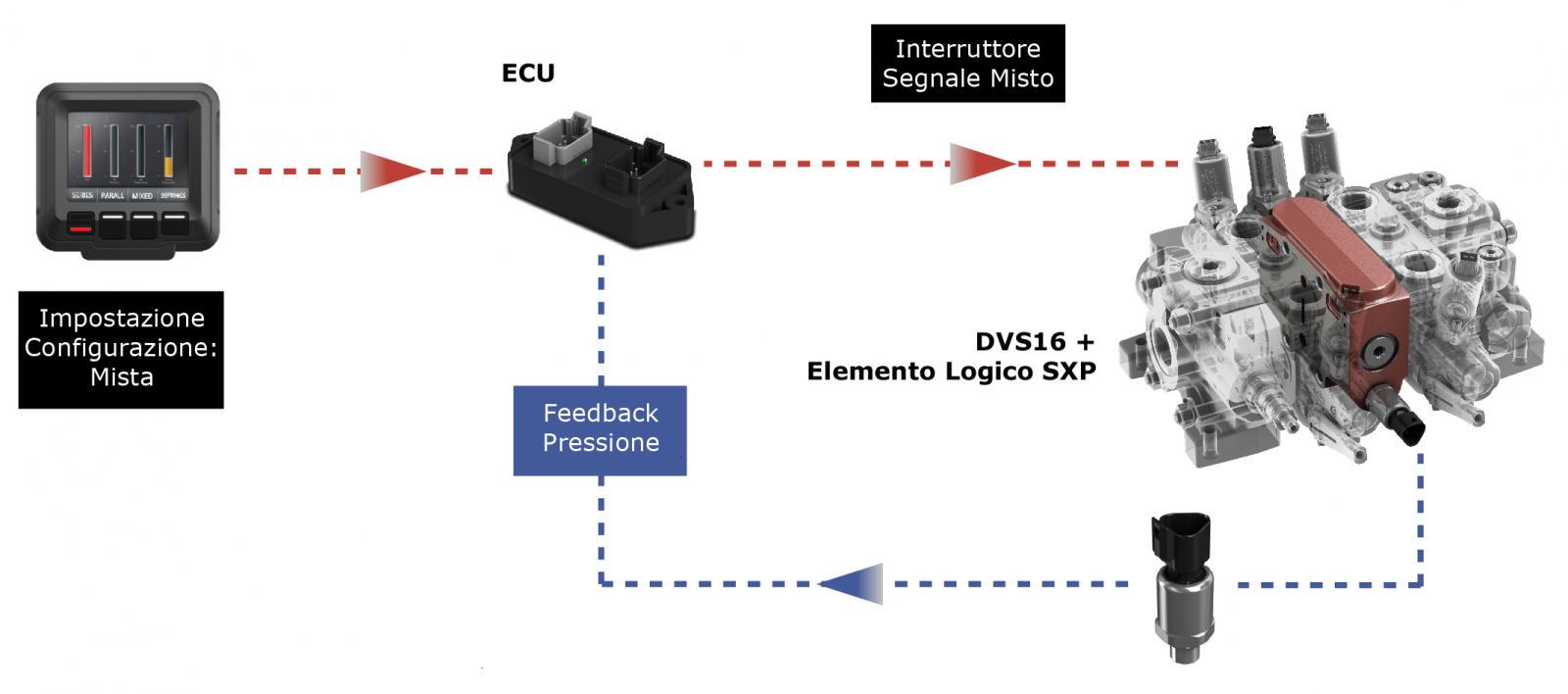

The switch of the logic element – core of the SXP EVO system – is possible thanks to an integrated solenoid valve, appropriately managed by the system’s electronics.

The complete system (see scheme) is indeed equipped with a sensor to detect the pressure of the hydraulic circuit and an ECU. This layout enriches the solution created on the valve, offering a high flexibility to the OEM but also to the end user thanks to the possibility of setting and customizing the work mode appropriately.

The work mode can be simply set by selecting it on the control panel.

In the MIXED system the circuit works as series circuit until the pressure sensor detects a pressure value that requires the switching to Parallel configuration.

By selecting the appropriate mode, one could even choose to work with fixed configurations, i.e. exclusively in SERIES or PARALLEL without switching.

Series or Parallel? Both!

The idea of combining the characteristics of two constructively different circuits in a single system stems from a careful analysis of these two systems:

the Series circuits allow to increase the speed of the loaders since in the first phase the oil is recovered from the return of the boom and not dissipated to tank.

Furthermore the controllability of the machine is improved since the simultaneous boom and bucket movements are completely controlled and guaranteed even with very different pressure loads.

On the other hand, in Series circuits, in case of simultaneous use, the pressure summation limits the maximum load capacity of the machine.

This is the reason why today some OEMs prefer the Parallel circuits in order to maximize the lifting capacity and to avoid the annoying effect of the series circuit: if the cylinders of a function reach their stroke end, also the cylinders of the other function stop.

Clearly these circuits are not free from defects: in case of simultaneous use and depending on the movement and the position of the load, a correct controllability of both movements is not granted.

Thanks to the new Walvoil SXP patented system it is possible to overcome the traditional dichotomy between Series circuit valves (which optimize speed and controllability) and Parallel circuit valves (which optimize load capacity), using a system that combine the positive features of both circuits.

The innovation is achieved with a simple device which can be inserted as an additional section into Walvoil wide range of valves or it can be totally integrated in a completely new and customized solution with advantages in terms of cost.

The system prototypes have already been manufactured and tested in the field, showing big advantages of this solution: in specific conditions the cycle time of the machine has been reduced by over 20%..

Professional users have confirmed ease of use and working comfort.

SXP EVO: a complete system

The SXP EVO system is completed by a new innovative HJW Heavy Duty Joystick: an electronic joystick, characterized by its ‘robust design’. Thanks to its characteristic modularity it can be provided with mechanical or electromagnetic detent, typically used on the Loader application.

Particulary robust and performing, it can be equipped with all the handles and options of Walvoil wide range. It has been set up to communicate with Walvoil control units in order to implement the complete system logic in a simple and efficient solution.

The different Fan Drive modules and the brand new Group 3 gear pump complete the Walvoil specific solution for wheel loaders.

To sum up, the advantages of the SXP EVO patented solution are:

• Loader productivity increased up to 20%

• Perfect simultaneous movements of Boom and Bucket thanks to normally in Series layout

• Higher controllability and comfort for the user

• Distribution of oil flow between Series and Parallel circuits

• The maximum load capacity is not influenced thanks to the switching to parallel configuration

• When the cylinder of a function reaches its stroke end, the cylinder of the other function doesn’t stop

• Additional flexibility thanks to the complete electronic system: possibility to set the pressure change value or to intentionally select the operating mode

• Combinable to the new HJW electronic joystick for heavy use, with integrated electromagnetic detent

• Complete system with integration of components, Fan motor and gear pumps included.

Walvoil Communication & Marketing

walvoil@walvoil.com

Tel. 0039.0522.932411

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS