WALVOIL'S NEW INNOVATION CENTER AT THE SERVICE OF MAJOR SYSTEM INTEGRATION AND FLEXIBILITY ON OFF-HIGHWAY VEHICLES

Walvoil is set to participate in the next edition of bauma, the 34th world trade fair for construction machinery, mining, construction vehicles and construction equipment, to be held from 7-13 April 2025 in Munich, Germany: Hall A3, booth 339.

Its presence will be in line with some of the trends identified by bauma 2025, focused on ‘Climate Neutrality’, ‘Alternative Drive Concepts’ and ‘Sustainable Construction’ and expressed by its new Hydraulic Digital Solutions, as well as in giving visibility to a project launched in 2023 and now a reality: that of the new Innovation Center, the beating heart of all Research & Development activities, and at the service of the Walvoil Group in Italy and worldwide.

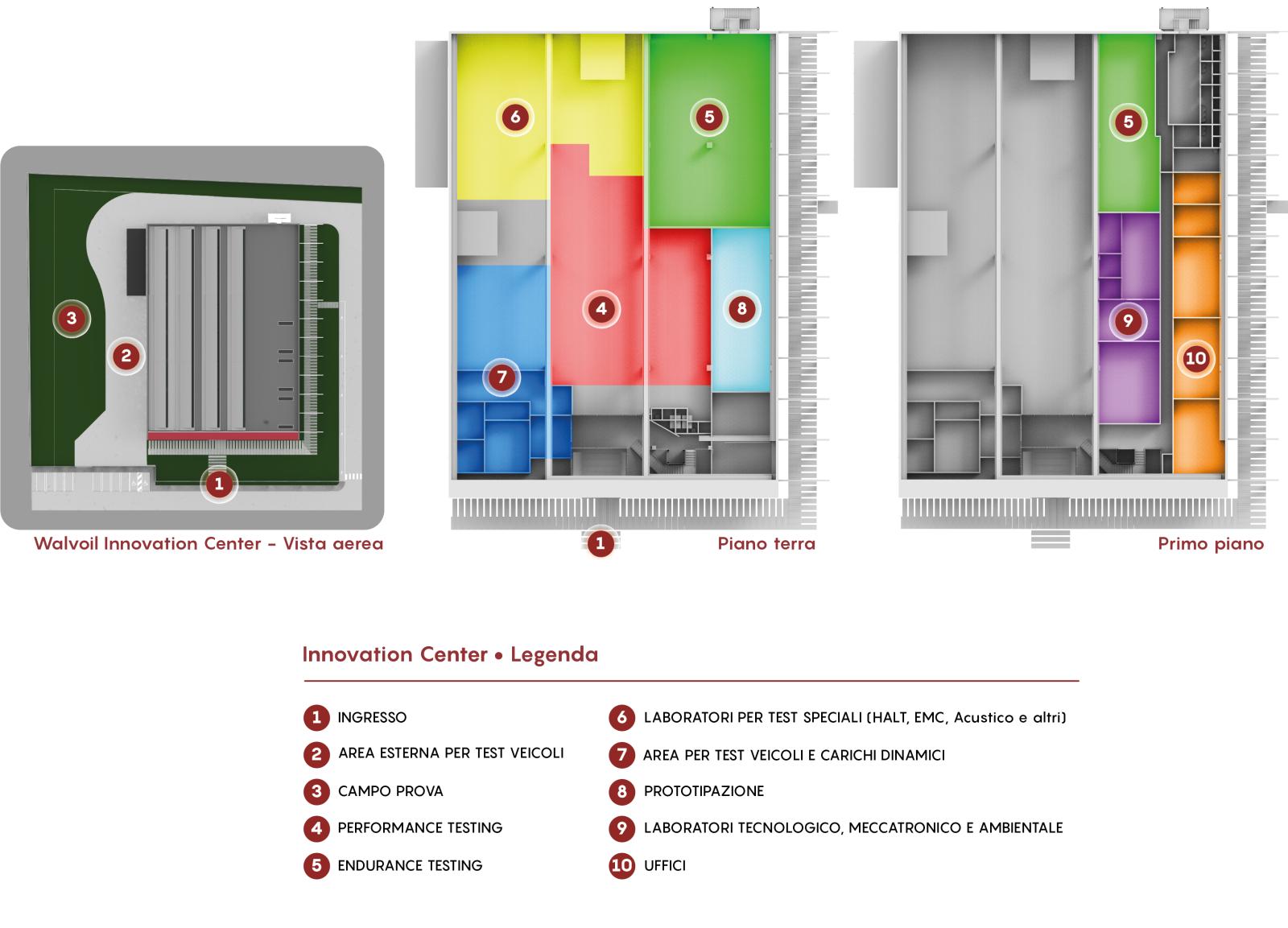

Innovation Center and expanded production plant in Cavriago, Reggio Emilia, Italy

Walvoil's Innovation Center was born in 2023 as part of an investment plan of more than thirty million Euros, with the main objective of establishing a centre of excellence in research in the field of hydraulics, and to enable the company to expand and deepen its innovation, development and testing capabilities.

An evolution of the previous Test Department, the centre covers over 3000 m2 and an external area of almost 2000 m2 dedicated to vehicle testing, and can count on around 30 specialised employees.

Innovation Center render: global overview

Thanks to the 140 different test equipment in the areas of Performance, Materials Technology, Oleodynamic

Endurance, Mechanical Endurance, Special Tests (environmental, vibration, acoustic, electric, etc.), in and

outdoor Vehicle Testing and the centre's 3,300 kW of installed power, Walvoil can carry out

- research and testing activities in every field of hydraulics, verification and experimentation on material characteristics and in the development of innovative production processes;

- validation of new high-performance, safe, reliable, digitised products with particular attention to energy saving and environmental sustainability;

- applications and system integrations on vehicles in sectors such as earth moving, agriculture, lifting, industrial vehicles, taking into account both customer needs/requirements and international standards.

Innovation Center: internal areas and laboratories

It is especially in the activities on the vehicles available at the Innovation Center, either its own or those of customers, that Walvoil is committing many of its resources, so as to make a difference both in the development of more advanced and performing components, as the mobile machinery market now requires, and in the design and application of more integration with electronics and the creation of greater added value in terms of system flexibility.

Particularly in recent years, Walvoil has strongly invested in the integration of its components in order to realize system solutions aimed at saving energy and increasing operating performance and operator comfort.

Testing activity on a performance bench

The digitization of components and the sensorialization of vehicles are the key to creating systems with high added value, which, thanks to the use of software and advanced control systems, are able to define the functionality of the machines of the future.

Walvoil's engineering approach involves the extensive use of simulation, which, with the help of digital models of components and vehicles, makes it possible to assess various scenarios in advance and optimise software development with software-in-the-loop and hardware-in-the-loop techniques. With this extremely flexible approach, shared with its main commercial partners, Walvoil is creating a modular and configurable system of logics and functions that can be adapted to the most diverse application areas, in full compliance with international standards and safety requirements.

Vehicle testing

Research, Innovation and Experimentation represent fundamental values for the company, which has always been dedicated to the creation of advanced solutions and their application at the world's leading machine manufacturers.

In the last 15 years Walvoil has collaborated with many Universities and Research Centres, both Italian and foreign, with an increasing presence at international conferences in the sector, presenting, together with several academic institutions, appreciated research works submitted to peer-review by the international scientific community of the hydraulics sector.

The new Innovation Center, thanks to the most innovative technologies and tools, now also sets no limits to the company in investigating the potential ‘breakthrough technologies’ of the future.

The only one of its kind in Italy, and one of the few in the world, it is proposed as a reference laboratory for Research in the field of hydraulics and mechatronics in the Emilia-Romagna region, thus enabling the company to carry out operational tasks, degree and doctoral theses, as well as with other research centres, such as the CNR, with which Walvoil can boast a long-lasting collaboration relationship.

As already amply demonstrated with the previous Test Department, Walvoil is ready to offer its testing capabilities not only to the academic research world, but also to its customers

The reason for this investment is explained by Fabio Marasi, President and CEO of Walvoil, who proudly comments on it as ‘a big step forward for us as a company. We wanted to give further legs to the company's potential. To do this, we once again chose our territory: this is where our roots are, and this is where it all began. It is our will and responsibility as a company to invest in the development of our activities in the Reggio Emilia area and in enhancing the skills and know-how of our employees, an essential and distinctive strength of our Group'.

Davide Mesturini, R&D Director, commented that: ‘the Innovation Center is a real upgrade for our area, a recognition of its strategic importance. We represent the driving heart of innovation and the conception of new products. This state-of-the-art centre is a further step in raising Walvoil's standards for quality and design. It gives us additional possibilities to go further in devising better solutions in terms of production and efficiency, and to accompany our customers even better in their implementation in Italy and around the world‘’.

Andrea Ferrari, Global Sales & Marketing Director, added: ‘This upstream investment in design and downstream investment in production allows us to increase our competitiveness at international level and, in particular, to bring the product closer to the application of our customers’ machines.

Walvoil Communication & Marketing

walvoil@walvoil.com

Tel. 0039.0522.932411

DISCOVER OUR NEW PRODUCTS

DISCOVER OUR NEW PRODUCTS